Conclusions

-

1.

In niobium alloys containing up to 10% each of Zr and C (atomic fraction) cooled during crystallization at rate of 101–105 °C/sec three phases form: α-solid solution based on niobium, Nb2C carbide with a hcp-lattice, and (Nb, Zr)C type carbide with a fcc-lattice.

-

2.

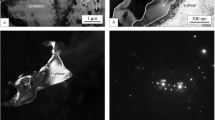

With crystallization at a rate of vcool=101–103. °C/sec a dendritic structure forms in alloys, at a cooling rate of 105 °C/sec it is cellular, and with an increase in crystallization rate there is a reduction dendrite parameter and cell size (to 1–5 μm with vcool=105 °C/sec).

-

3.

An increase in cooling rate during crystallization from 101 to 105 °C/sec promotes considerable refinement and a change in the nature of carbide phase distribution forming during crystallization.

-

4.

An increase in crystallization rate causes an increase in the amount of carbon and zirconium dissolved in niobium. Subsequent heating up to 1900°C leads to decomposition of rapidly quenched solid solution with separation of dispersed (Nb, Zr)C carbide platelets, but morphology and the amount of eutectic carbide does not change and grain growth is not observed.

Similar content being viewed by others

Literature Cited

V. K. Grigorivich and E. N. Shtefel', Dispersion Hardening of Refractory Metals [in Russian], Nauka, Moscow (1980).

V. I. Trefilov and V. F. Moiseev, Dispersed Particles in Refractory Metals [in Russian], Naukova Dumka, Kiev (1978).

V. I. Dobatkin and V. I. Elagin, Granular Aluminum Alloys [in Russian], Metallurgiya, Moscow (1981).

A. F. Belov, N. F. Anoshkin, and S. Kh. Faktkullin., Structure and Properties of Granular Nickel Alloys [in Russian], Metallurgiya, Moscow (1984).

A. Taylor and N. I. Doyle, "The solid solubility of carbon in Nb and Nb-rich Nb-Hf, Nb-Mo, and Nb-W alloys,". J Less Common Met.,13, No. 5 511–529 (1967).

I. I. Druzhinin, A. M. Zakharov, and I. I. Novikov, "Phase equilibrium in the niobium corner of the N-Zr-C system," Izv. Vyssh. Uchebn. Zaved., Tsvetnye Met., No. 1, 118–121 (1972).

S. S. Ordan'yan, A. I. Avgustinik, and V. Sh. Vigdergauz, "Structure of alloys of the Nb-Zr-C system," Zh. Prikl. Khim.,39, No.2, 312–317 (1966).

A. A. Bochvar, Study of Mechanism and Kinetics of Eutectic Type Alloy, Crystallization [in Russian], ONYI, Moscow-Leningrad (1981).

Yu. N. Taran and I. S., Miroschnichenko, "Three types of eutectic structure," in: Growth and Defects of Crystals [in Russian], Naukova Dumka, Kiev (1972).

A. M. Zakharov, Constitution Diagrams for Binary and Ternary Systems [in Russian], Metallurgiya, Moscow (1978).

E. N. Shtefel', "Carbide strengthening of niobium alloys," in: High-Temperature and Heat-Resistant Metallic Materials [in Russian], Nauka, Moscow (1987).

Additional information

A. A. Baikov Institute of Metallurgy, Moscow. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 4, pp. 32–35, April, 1989.

Rights and permissions

About this article

Cite this article

Sheftel, E.N., Bannykh, O.A., Usmanova, G.S. et al. Effect of crystallization rate on the structure of alloys in the Nb-Zr-C system. Met Sci Heat Treat 31, 271–277 (1989). https://doi.org/10.1007/BF00715802

Issue Date:

DOI: https://doi.org/10.1007/BF00715802