Conclusions

-

1.

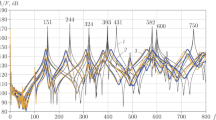

The decrement of vibrations of wrought aluminum is lower than that of magnesium, and amounts to 0.01 at an amplitude of 2.9·10−4.

-

2.

Alloying reduces the damping capacity of aluminum. A sharp reduction of the decrement with alloying and a low level of the decrement (0.001) are characteristic of systems with relatively high solubility of the components and a substantial increase of hardness due to alloying.

-

3.

For systems with low solubility of the components the decrement decreases negligibly with alloying and has a higher value (0.002–0.005).

Similar content being viewed by others

Literature cited

D. James, Materials Science and Engineering,4, No. 1 (1969).

J. Jensen, Light Metal Age, 22, snNo. 11 (1964).

G. Weissman and W. Babington, J. of Environmental Sciences,2, No. 5 (1966).

G. S. Pisarenko et al., Vestnik Mashinostroeniya, No. 10 (1969).

Yu. K. Favstov, Zavod. Lab.,25, No. 5 (1959).

M. Hansen and K. Anderko, Constitution of Binary Alloys, McGraw-Hill (1958).

M. E. Drits, et al., Izv. Akad. Nauk SSSR, Metally, No. 2 (1970).

Additional information

A. A. Baikov Institute of Metallurgy. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 10, pp. 67–69, October, 1971.

Rights and permissions

About this article

Cite this article

Drits, M.E., Rokhlin, L.L. & Ryuchina, G.V. The damping capacity of wrought aluminum alloys. Met Sci Heat Treat 13, 878–880 (1971). https://doi.org/10.1007/BF00713831

Issue Date:

DOI: https://doi.org/10.1007/BF00713831