Conclusions

-

1.

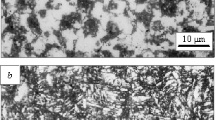

Electrothermal treatment (electrohardening+electrotempering) of complex alloy steel 8Kh4V2S2MF increases the hardness to HRC 65-67.

-

2.

Electrothermal treatment (hardening with holding 20 sec at austenitizing temperature and electrotempering) of ledeburitic steel Kh12M makes it possible to obtain a hardness of HRC 61-63.

-

3.

To obtain a long service life for tools subject to large alternating loads it is expedient to have some amount of retained austenite in the structure.

Similar content being viewed by others

Literature Cited

Yu. A. Geller, V. F. Moiseev, and G. A. Okolovich, "Fundamentals of alloying cold-worked die steels subjected to secondary hardening", Metalloved. Term. Obrab. Met., No. 2, 9, (1973).

Yu. A. Geller, Tool Steels [in Russian], Metallurgiya, Moscow (1975).

G. V. Kozyrev and G. V. Toporov, "Effect of retained austenite on the impact fatigue strength of steel", Metalloved. Term. Obrab. Met., No. 12, 45 (1973).

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 11, pp. 54–56, November, 1978.

Rights and permissions

About this article

Cite this article

Kholin, A.S., Abramov, A.I., Chekhovoi, A.N. et al. Electrothermal treatment of high-alloy die steels. Met Sci Heat Treat 20, 936–938 (1978). https://doi.org/10.1007/BF00713761

Issue Date:

DOI: https://doi.org/10.1007/BF00713761