Conclusions

-

1.

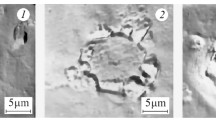

In the surface layer of rolls used for cold rolling and quenched after heating with industrial-frequency electric current, a cementite-type carbide is contained, which has high values of the lattice parametersa, b, and c indicating that it is alloyed. The degree of alloying linearly increases with distance as one moves from the interior to the surface.

-

2.

The lowest concentration of the alloyed cementite (4%) is observed at a distance of 5 mm from the surface of the roller, whereas the highest value (11%) is observed at a distance of 50 mm.

-

3.

The peak on the concentration-distribution curve of cementite, the inflection on the hardenability curve, as well as the greatest amount of the cementite substructure (maximum line width) are observed at a distance of 30 mm from the surface of the roll in the bainitic transformation region.

Similar content being viewed by others

Literature cited

A. I. Kondrashov, V. A. Kamalov, and K. F. Gruzhienko, "Perfecting the commercial heat-treatment process of cold-rolling rolls," in: Forging and Heat Treatment: An Anthology of Papers [in Russian], TsNITIMASH, Leningrad, No. 5, 70–82 (1959).

B. A. Brusilovskii, V. N. Zaika, and A. M. Ovcharenko, "An x-ray method for determining the cementite content in steel," in: Apparatus and Methods of X-Ray Analysis: An Anthology of Papers [in Russian], Mashinostroenie, Leningrad, No. 40, 236–240 (1990).

E. Houdremont, Special Steels. Vols. I & II [Russian translation], Metallurgiya, Moscow (1966), p. 1274.

B. A. Brusilovskii, V. N. Zaika, and T. E. Piskareva, "Residual austenite in the surface layer of cold-rolling rolls," Fiz. Met. Metalloved.,67, No. 6, 1134–1137 (1989).

M. E. Blanter, Theory of Heat Treatment [Russian translation], Metallurgiya, Moscow (1984), p. 327.

M. V. Gedeon, G. P. Sobol', and I. V. Paisov, Heat Treatment of Cold-Rolling Rolls [in Russian], Metallurgiya, Moscow (1973), p. 344.

B. A. Brusilovskii and F. I. Ivanov, "An x-ray diffraction investigation of low-temperature annealing of cold-rolling rolls," Fiz. Met. Metalloved.,19, No. 1, 147–149 (1965).

Additional information

Kramatorsk Industrial Institute. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 11, pp. 2–4, November, 1992.

Rights and permissions

About this article

Cite this article

Brusilovskii, B.A., Shashko, A.Y. Cementite-type carbide in the surface layer of cold-rolling rolls. Met Sci Heat Treat 34, 661–664 (1992). https://doi.org/10.1007/BF00712422

Issue Date:

DOI: https://doi.org/10.1007/BF00712422