Conclusions

-

1.

Alloy 30NKhTYuD may contain four phases: the \gg solid solution, \gg\t' phase \3- Ni3(Al, Ti), the Cr\ga phase, and titanium carbide (TiC).

The composition and quantity of the γ, γ′, and Crα phases depend to a considerable extent on the heat treatment. The TiC is primary carbide, the composition and quantity not changing with heat treatment.

-

2.

The largest amounts of \gg\t' and Cr\ga phases are formed during aging at 700–800\dg. The composition of the \gg\t' and Cr\ga phases changes negligibly in the process of heat treatment. The composition of the solid solution undergoes greater changes.

-

3.

The high hardness, wear resistance, and contact fatigue strength of the alloy are the result of complex hardening in the process of aging due to the precipitation of \gg\t' and Cr\ga phases.

-

4.

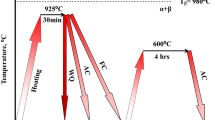

The optimal heat treatment for alloy 30NKhTYuD is water quenching from 1150\dg and aging at 750\dg for 4–10 h.

-

5.

The high concentrations of chronium and aluminum are responsible for the high scale resistance and corrosion resistance of the alloy in operation under various climatic conditions.

Similar content being viewed by others

Literature cited

N. F. Lashko et al., Physicochemical Phase Analysis of Steels and Alloys [in Russian], 2nd ed., Metallurgiya, Moscow (1978), p. 336.

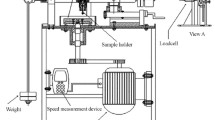

O. N. Chermenskii, M. M. Amelekhin, and I. A. Burlakov, Mechanical Testing of Bearing Materials (Review) [in Russian], NIINavtoprom, Moscow, p. 62.

L. S. Palatnik, Ya. I. Kagan, and N. B. Fat'yanova, "Stepped decomposition of alloy 40KhNYu," Metalloved. Term. Obrab. Met., No. 1, 46 (1980).

Additional information

All-Union Institute of Aviation Materials. All-Union Scientific Design-Engineering Institute of the Bearing Industry. Translated from Metallovedenie i Termicheskaya Obratkova Metallov, No. 10, pp. 26–29, October, 1981.

Rights and permissions

About this article

Cite this article

Talakin, N.I., Pavlova, Z.V. & Shchurkova, Z.V. Heat treatment and properties of precipitation-hardening wear-resistant alloy 30NKhTYuD. Met Sci Heat Treat 23, 694–697 (1981). https://doi.org/10.1007/BF00712406

Issue Date:

DOI: https://doi.org/10.1007/BF00712406