Conclusions

-

1.

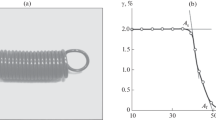

The resistance of alloy TN-1K to deformation\(\bar \dot \varepsilon\) increases with the rate of deformation in the range 10−3-103 sec−1, as indicated by an increase in the strength properties σ0.2, σu, σf, and the energy parameter Ap. Under the same conditions the deformation properties δ and ψ undergo no statistically significant change.

-

2.

The susceptibility of alloy TN-1K to brittle fracture does not vary within the investigated range\(\bar \dot \varepsilon\) = 3.2·10−3−690 sec−1. This is also confirmed by values of the energy absorption parameter β.

Similar content being viewed by others

References

V. A. Likhachev, S. L. Kuz'min, and Z. P. Kamentseva, The Shape Memory Effect [in Russian], Leningrad Univ. (1987).

N. N. Bashanova, N. F. Zhebyneva, and S. G. Fedotov, et al., "Effect of applied stress on the shape memory effect in alloys based on titanium nickelide," Metalloved. Term. Obrab. Met., No. 1 (1988).

Yu. K. Kovnerystyi, L. A. Matlakhova, M. N. Matveeva, et al., "Characteristics of the shape memory effect in rapidly quenched TiNi−TiCu alloys", Izv. Akad. Nauk SSSR, Met., No. 5, 138–142 (1988).

N. K. Foteev, Technology of Electroerosion Treatment [in Russian], Mashinostroenie, Moscow (1980).

N. N. Popov, "Mechanical properties of structural materials in static and dynamic loading", Metalloved. Term. Obrab. Met., No. 4, 8–10 (1987).

N. N. Popov and V. M. Barinov, "Vertical hammer for the dynamic testing of materials", Zavod. Lab.,52, No. 5, 77–79 (1985).

N. N. Popov, A. K. Krinitskii, and Yu. B. Khomutinin, Zavod. Lab.,52, No. 10, 38–40 (1986).

M. N. Stepanov, Statistical Methods for the Treatment of Mechanical Test Results (Handbook)[in Russian], Mashinostroenie, Moscow (1985).

N. N. Popov, "Resistance of aluminum alloy 1201 to plastic deformation at various deformation rates", Metalloved. Term. Obrab. Met., No. 8, 56–61 (1989).

N. N. Popov, V. N. Pozdov, and L. V. Polyakov, "Resistance of the corrosion-resistant steels 12Kh18N10T and A43UP to plastic deformation at various deformation rates", Probl. Prochn. No. 7, 62–66 (1988).

A. Khol'tser and R. Braun, "Mechanical properties of metals under dynamic compression," in: Theoretical Principles of Engineering Calculations: Proceedings of the American Society of Eng. Mech. (Ser. D), No. 3, 67–78 (1979).

Additional information

All-Union Scientific-Research Institute of Experimental Physics, Arzamas-16. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 11, pp. 26–28, November, 1993.

Rights and permissions

About this article

Cite this article

Popov, N.N., Mart'yanov, V.A. Resistance of titanium nickelide TN-1K to deformation at rates of 10−3-103 per second. Met Sci Heat Treat 35, 639–642 (1993). https://doi.org/10.1007/BF00712286

Issue Date:

DOI: https://doi.org/10.1007/BF00712286