Abstract

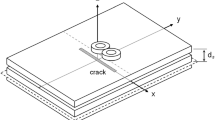

Nondestructive inspection of flat and long cylindrical metallic-surface layers is conveniently dealt with using the results of wave propagations in a one-dimensionally stratified medium. Analytical solutions for some special profiles are obtained, and perturbation technique is used to obtain results for more frequently encountered profiles.

Similar content being viewed by others

References

H. Hochschild, Electromagnetic methods of testing metals,Progress in Appl. Mater. Res. 1:59–109 (1959).

K. A. Fowler and H. P. Hatch, Non destructive determination of case depth of carburized steel by harmonic voltage analysis,Mat. Eval. 145–149 (1966).

H. P. Hatch and K. A. Fowler,Development in the Harmonic Analysis Method for the Non Destructive Determination of Case Depth of Carburized Steel, Technical Report SA-TR19-1520, AMCMS CODE 4930.1, (Springfield Armory, Springfield, Massachusetts, May 20, 1966).

H. P. Hatch and K. A. Fowler,Electromagnetic Method of Non Destructively Examining Components for Excessive Decarburization, Technical Report SA-TR 19-1508, AMCMS CODE 4230.6018, 60.01, Springfield Armory, Springfield, Massachusetts, April 14, 1964.

H. Larson, Multifrequency eddy current testing of case hardened cylinders, A theoretical and experimental analysis,Eur. Vortrags. Zerstor. Materi. 20:199–206 (1978).

H. Larson, Eddy current testing of surface hardened material,Eighth World Conference on Non Destructive Testing (1976).

N. N. Zatsepin, On certain new magnetic and electromagnetic non destructive testing methods and aids,Ninth World Conference on Non Destructive Testing (1977).

S. Kh. Passi, S. B. Biryukov, A. V. Zusman, and V. B. Ginzburg, An electroinduction multifrequency unit for determining the depth of decarburization of bearing steel bars,Defektoskopiya 8:67–76 (1972).

G. M. Popov, Device for testing the surface decarburization of calibrated pack steel,Defektoskopiya 7:22–29 (1971).

F. N. Nuriev, G. V. Zaitsev, and V. A. Charov, Instrument for measuring the thickness of decarburized layers,Defektoskopiya 6:80–85 (1970).

M. N. Mikheev, B. M. Neizvestnov, G. V. Bida, G. V. Surin, and V. M. Morozova, Magnetic inspection of heat treatment quality of large bearing parts,Defektoskopiya 13:140–143 (1977).

M. N. Mikheev, E. S. Gorkunov, and F. N. Dunaev, Non destructive magnetic inspection of hardened and tempered parts of low-alloy constructional and plain carbon steels, Parts I and II,Defektoskopiya 13:7–18 (1977).

M. N. Mikheev, E. S. Gorkunov, V. V. Grebenschikov, N. V. Remez, and M. P. Shchetkova, Electromagnetic inspection of heat treated small parts of grade 40Kh steel for hardness,Defektoskopiya 14:62–68 (1978).

M. N. Mikheev, B. M. Neizvestnov, V. M. Morozova, and G. V. Surin, Coercimeters with attached electromagnets,Defektoskopiya 5:131–133 (1969).

M. N. Mikheev and G. Gorkunov, Magnetic methods of monitoring quality of heat-Treatment,Ninth World Conference on Non Destructive Testing (1977).

V. A. Sandovskii and Sh. G. Battalov, Determining the mechanical strength of steels from the spectral content of the EMF generated by a coil with a ferromagnetic core,Defektoskopiya 11:78–82 (1975).

E. Peterson, Harmonic production in ferromagnetic materials at low frequencies and low flux densities,Bell System Technical Journal 7:762–796 (1928).

A. D. Pokrovskii and Yu. P. Khvalebnov, Analysis of the higher harmonic signals of measuring transducers,Defektoskopiya 13:83–88 (1977).

H. G. Beech, Case depth measurement by eddy current technique,Heat Treatment of Metals 1:22–26 (1975).

M. M. Belenkova, An instrument for measuring the depth of nitrided layer on austenic steel parts,Defektoskopiya 14:68–74, (1978).

V. V. Levitin, Testing the surface decarburization of calibrated Sh Kh 15 steel bars,Defektoskopiya 6:25–32 (1970).

E. V. Aronson, G. V. Bida, V. M. Kamardin, M. N. Mikheev, and D. M. Poner, Magnetic test of mechanical properties of rolled 20K and 0962 steel sheets,Defektoskopiya 13:, 121–124, (1977).

M. K. Balabanova, V. V. Vlasov, A. F. Dubkov, and Yu. S. Subbottin, Use of an electromagnetic induction flaw detector with a striding search system for checking the depth of surface decarburization of bearing steel rods,Defektoskopiya 5:84–91 (1969).

C. Flambard, Non destructive testing of heat treatment penetration,Mechanique — Materiaux — Electricite', No. 317 (1976).

A. Ya. Rachok, The effect of depth of decarburization layers of ball bearing steel on the impedance of a feed-through coil,Defektoskopiya 1: Part 5, 57–61 (1965).

I. V. Mel'nikov, L. A. Savikovskii, E. N. Semenov, and A. N. Filippovich, Eddy current inspection of the hardening and tempering quality of thin walled bearing races,Defektoskopiya No. 6, 41–47 (1977).

N. M. Rodigin, L. S. Pravdin, V. P. Syrochkin, B. A. Sirotkin, R. N. Utochkin, and V. D. Sukhanov, Inspection of work hardening of steel shafts by the eddy current method, Part I, II, and III,Defektoskopiya 6:117–130 (1970).

D. Hadfield, Magnetic measurement of the hardness of metals,Metal Treatment and Drop Forging 22:153–159 (1955).

R. C. McMaster, W. C. Harmon, and D. G. Pullen, Eddy current inspection (non destructive testing part),Metals Handbook, (Ronald, New York, 1959)

J. R. Wait,Electromagnetic Waves in Stratified Media, (Pergamon Press, Oxford, 1970).

J. R. Wait and R. L. Gardner, Electromagnetic nondestructive testing of cylindrically layered conductors,IEEE Inst. & Meas. IM-28, 159–161 (1979).

J. R. Wait, Fields of a horizontal dipole over a stratified anisotropic half space,IEEE Antenna & Prop. AP-14, 790–792 (1966).

J. R. Wait, The electromagnetic basis for nondestructive testing of cylindrical conductors,IEEE Inst. & Meas. IM-27, 235–238 (1978).

E. G. Belikov, V. G. Gerasimov, and Yu. Ya. Ostanin, Theory of laid-on shielded transducer for inspection of multilayer products,Defektoskopiya No. 5, 52–61 (1977).

C. C. Cheng, C. V. Dodd, and W. Deed, General analysis of probe coils near stratified conductors,Int. J. of Non Destructive Testing 3:109–130 (1971).

J. A. Roumeliotis, J. G. Fikioris, and G. P. Gounaris, Electromagnetic scattering from an eccentrically coated infinite metallic cylinder,J. Appl. Phys. 51:4488–4493 (1980).

H. L. Libby,Introduction to Electromagnetic Non Destructive Test Methods, (Wiley-Interscience, New York, 1971).

T. Sato, Y. Suzuki, S. Saito, and Y. Inui, Calculation of magnetic field taking into account eddy current and non-linear magnetism,Elec. Eng. Japan,96:96–102 (1976).

R. M. Bozorth,Ferromagnetism, (D. Van Nostrand Inc., Princeton, New Jersey, 1957).

J. Galejs, E.L.F. waves in the presence of exponential ionospheric conductivity profiles,Trans. I.R.E. AP-9 (1961).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Tran-Cong, T. Eddy current solutions applicable to the problem of nondestructive inspection of flat and cylindrical surface layer. J Nondestruct Eval 4, 29–38 (1984). https://doi.org/10.1007/BF00711098

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF00711098