Conclusions

-

1.

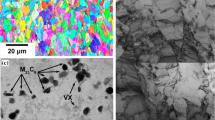

After austenization at 1150°C and quenching in oil, precipitation of clusters enriched in Cr and C occurs in the austenite of high-chromium ledeburitic steel. With tempering temperature increasing up to 300°C the number of clusters increases, and at the same time they start to transform into alloyed cementite (Cr, Fe)3C. The transformation proceeds at temperatures above 400°C. At that time the cementite particles grow and their number decreases. During a single tempering at 520°C, the particles become almost-completely dissolved in the austenite.

-

2.

The processes of particle precipitation in austenite influence its mechanical properties. Increasing the number of particles in austenite at tempering temperatures up to 300°C increases the microhardness and the fracture toughness. Fracture toughness decreases with increase of size and distance between the particles.

-

3.

Variation of the number of clusters and cementite particles with tempering temperature is the main reason for the thermal stability of residual austenite in the steel studied. Cementite instability, and its dissolution in austenite at 520°C, causes the secondary transformation into martensite during the cooling process.

Similar content being viewed by others

Literature cited

A. P. Gulyaev, Metallurg., No. 12 (1936).

P. M. Yushkevich, "On the nature of strengthening of a quenched free-cutting steel during tempering," Fiz. Met. Metalloved.,8, No. 6, 896 (1959).

F. Jeglitsch et al., Härterei-Techn. Mitt.,24, No. 1, 15–23 (1969).

G. V. Korotushenko, "Nature of the secondary austenite-martensite reaction during tempering of free-cutting steels," Izv. Vyssh. Uchebn. Zaved., Charn. Metall., No. 8, 128 (1960).

E. Hornbogen and W. Meyer, Z. Metallkunde,56, No. 5, 297 (1967).

E. Hornbogen and W. Meyer, Arch. Eisenhüttenwesen,39, No. 1, 73 (1968).

B. G. Serebrennikova and M. E. Blanter, "On the nature of thermal stability of austenite," Metalloved. Term. Obrab. Met., No. 2, 7 (1972).

M. E. Blanter, "Martensite transformations and mechanical state of phases," Metalloved. Term. Obrab. Met., No. 5, 7 (1975).

R. S. 3642–72 Metalle, Prüfverfahren Ermittlung der Bruchzähigkeit bei slatischer Beigung.

A. A. Zhukov and M. A. Krishtal, "On the thermodynamic activity of alloy-forming elements," Metalloved. Term. Obrab. Met., No. 7, 70 (1975).

S. F. Yurev and B. N. Bruk, "Redistribution of carbon and of grain boundaries of heterogeneous microvolumes in steel during tempering," Dokl. Akad. Nauk SSSR,104, No. 4, 533 (1955).

A. Cottrell, Trans. AIME,212, 192 (1958).

T. Prnka, "Quantitative relations between parameters of dispersed precipitants and mechanical properties of steel," Metalloved. term. Obrab. Met., No. 7, 3 (1975).

P. V. Ryabko and K. P. Ryaboshapka, "Plastic deformation and brittle failure of heterogeneous system," in: Metallofizika, No. 43, 3 (1972).

Additional information

People's Republic of Bulgaria. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 8, pp. 35–39, August, 1984.

Rights and permissions

About this article

Cite this article

Tolev, N. Influence of precipitation processes on the mechanical properties and redidual austenite stability of high-chromium tool steel. Met Sci Heat Treat 26, 608–612 (1984). https://doi.org/10.1007/BF00707801

Issue Date:

DOI: https://doi.org/10.1007/BF00707801