Conclusions

-

1.

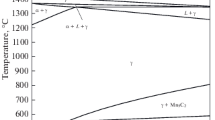

Melt purity has a marked effect on the level of mechanical properties for Fe−Mn alloys and the nature of their change with an increase in manganese concentration.

-

2.

For high-purity alloys strength properties increase markedly in the two-phase (ε+γ)-region. Alloy with 21–24% Mn has the maximum strength (σf = MPa; σ0.2 = 4.50 MPa).

-

3.

At the boundary of the (ε+γ)-and γ-regions for high-purity alloys "boundary" or concentration superplasticity is observed; a reduction in test temperature to −196°C is accompanied by an increase in relative elongation.

-

4.

For industrial purity alloys strength properties decrease gradually with a changeover from α- to ε- and γ-solid solutions. Strength and ductility properties of these alloys are insensitive to the position of the (ε+γ)- and γ-region boundary.

-

5.

With an increase in melt purity reserve ductility for Fe−Mn alloys increases, and this has been established by fractographic study of the nature of their failure.

Similar content being viewed by others

Literature cited

A. P. Gulyaev and T. F. Volynova, "Cold brittleness of α-, ε- and γ-solid solutions for alloys of the Fe−Mn system", Metalloved. Term. Obrab. Met. No. 2, 17–23 (1979).

T. F. Volynova and V. M. Mnasin, "Effect of melt purity on the cold brittleness threshold for alloy G29", Metalloved. Term. Obrab. Met., No. 3, 16–20 (1983).

T. F. Volynova and V. M. Mnasin, "Cold brittleness of industrial purity iron-manganese alloys", Metalloved. Term. Obrab. Met., No. 11, 36–41 (1983).

H. Schumann, "Gefüge und Eigenschaffen neideriggekohlter Stähle mit 25 bis 50% Mn", Neue Hütte,14, No. 29, 542–546 (1969).

I. N. Bogachev and V. F. Egolaev, Structure and Properties of Iron-Manganese Alloys [in Russian], Metallurgiya, Moscow (1973).

I. N. Bogachev, G. E. Zvigintseva, O. A. Khomenko, and I. F. Khil'kevich, "Mechanical properties of binary and ternary alloys", Metalloved. Term. Obrab. Met., No. 8, 29–31 (1975).

I. Ya. Georgieva, A. A. Gulvyaev, and E. Yu. Kondrat'eva, "Deformation twinning and mechanical properties of austenitic manganese steels", Metalloved. Term. Obrab. Met., No. 8, 56–58 (1976).

A. P. Gulyaev, T. F. Volynova, and I. Ya. Georgieva, "Phase transformation in alloys of the Fe−Mn system of high purity" Metalloved. Term. Obrab. Met., No. 3, 2–6 (1978).

L. S. Malinov, V. I. Konop, K. N. Sokolov, and T. P. Sverchkova, "Optimization of martensite transformation intensity during loading in chromium-manganese steels", Izv. Akad. Nauk SSSR, Met., No. 5, 141–148 (1976).

P. Yu. Volosevich, V. N. Gridnev, and Yu. N. Petrov, "Effect of manganese on packing defect energy in iron-manganese alloys", Fiz. Met. Metalloved.,42, No. 2, 372–376 (1976).

Additional information

I. P. Bardin Scientific-Research Institute of Ferrous Metallurgy, Moscow. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 6, pp. 58–63, June, 1984.

Rights and permissions

About this article

Cite this article

Volynova, T.F. Nickel-free iron-manganese alloys. Met Sci Heat Treat 26, 476–482 (1984). https://doi.org/10.1007/BF00707724

Issue Date:

DOI: https://doi.org/10.1007/BF00707724