Conclusions

-

1.

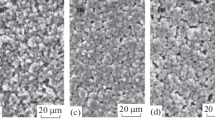

Zinc, applied to aluminum by the method of hot rolling (cladding), ensures longer corrosion resistance of products than when they are zinc-coated by hot dipping because in the former case the structure is homogeneous and there are no aluminum oxides in the zone of contact.

-

2.

Solders for the soft soldering of zinc-clad aluminum may contain tin, lead, or cadmium because these elements do not harm the integrity of the zinc coating in the soldered zone.

Similar content being viewed by others

Literature cited

Inventor's Certificate No. 238326 USSR. Method of Soldering Aluminum and Its Alloys.

I. N. Il'evskii, G. M. Mozhaiskaya, and I. E. Petrunin, "Corrosion resistance of soldered aluminum alloys," Fiz. Khim. Obrab. Mater., No. 5 (1968).

G. N. Smirnov, Progressive Methods of Soldering Aluminum [in Russian], Metallurgiya, Moscow (1981).

S. N. Lotsmanov (ed.) Handbook on Soldering [in Russian], Mashinostroenie, Moscow (1975).

Additional information

Technical University attached to ZIL. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 12, pp. 33–35, December, 1987

Rights and permissions

About this article

Cite this article

Mozhaiskaya, G.M., Trekina, M.I. Interaction of zinc coating with aluminum and liquid metals. Met Sci Heat Treat 29, 931–934 (1987). https://doi.org/10.1007/BF00707591

Issue Date:

DOI: https://doi.org/10.1007/BF00707591