Conclusions

-

1.

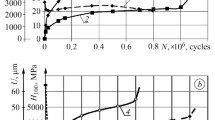

Under conditions of friction and wear of an equilibrium solid solution one observes solution of anodic components of the alloy in the lubricant and formation on the contact surface of a plasticized film of pure copper with a specific structure—low dislocation density and high density of vacancies. In this case the wear resistance increases sharply—to the point where wear is practically absent.

-

2.

During friction of unstable alloys and alloys susceptible to phase transformations the conditions are favorable for the formation of intermetallic compounds in local areas, which changes in principle the mechanism of the contact interaction—the wear resistance decreases considerably.

-

3.

Equilibrium and a single phase are the basic conditions for high wear resistance of copper-tin alloys during friction in surface-active lubricants.

Similar content being viewed by others

Literature cited

A. Roberts and A. Cameron, Trans. ASLE,18, No. 4, 270 (1975).

J. Ferrante and D. Buckley, Trans. ASLE,1, No. 15, 18 (1972).

I. Oda, M. Kimura, and K. Nakajima, Wear,20, No. 2, 159 (1972).

B. Lunn, Wear,8, No. 5, 401 (1965).

M. M. Khrushchov et al., "Friction of antifriction bronzes and brasses with and without lubrication," in: Friction and Wear in Machines [in Russian], Izd. Akad. Nauk SSSR (1962), p. 36.

A. De Gee and G. Vaessen, First European Trib. Congress, 1973, p. 137.

L. F. Kolesnichenko, É. G. Mamykin, and A. I. Yuga, "Working capacity of Cu-Pb alloys under conditions of sliding friction," in: Problems of Friction and Wear [in Russian], No. 4, Tekhnika, Kiev (1974), p. 69.

F. P. Bowden and D. Taybor, Friction and Lubrication of Solids [Russian translation], Mashinostroenie, Moscow (1968).

M. A. Krishtal and M. A. Vyboishchik, "Variation of the paremeters of diffusion along dislocations with the valence of diffusing elements," Fiz. Met. Metalloved.,38, No. 2, 356 (1974).

L. M. Rybakova, L. I. Kuksenova, and S. V. Bosov, "X-ray analysis of structural changes in a thin surface layer of metal during friction," Zavod. Lab., No. 3, 293 (1973).

L. I. Kuksenova and L. M. Rybakova, "Role of diffusion processes during friction of copper alloys," Fiz. Khim. Obrab. Mater., No. 1, 123 (1978).

L. M. Rybakova and L. I. Kuksenova, "Structure of the surface layer formed in the zone of contact during friction of copper under conditions of selective transfer," Fiz.-Khim. Mekh. Mater., No. 1, 100 (1976).

Additional information

Institute of Machine Science. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 12, pp. 19–22, December, 1979.

Rights and permissions

About this article

Cite this article

Rybakova, L.M., Kuksenova, L.I. & Samylkin, V.M. Effect of diffusional redistribution of alloying elements on the wear resistance of copper alloys. Met Sci Heat Treat 21, 916–919 (1979). https://doi.org/10.1007/BF00706626

Issue Date:

DOI: https://doi.org/10.1007/BF00706626