Conclusions

-

1.

Alloys of the Ni-Co-Cr-Nb system containing 15% Cr, 10% Nb, and 6.8–33.5% Co exhibit a distinct dispersion hardening effect, with high strength and elastic characteristics and satisfactory relaxation resistance at 500°.

-

2.

Cobalt (12.6–21.5%) increases the effect of precipitation hardening on the strength and elastic properties of Ni-15Cr-10Nb. The largest increase of these properties and the relaxation resistance is obtained with 21.5% Co.

-

3.

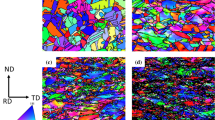

Transmission electron microscopy showed that the basic hardening phase in Ni-(Co)-Cr-Nb alloys is metastable γ″ phase (Ni3Nb) with a bct lattice (superstructure of the D022 type) that precipitates during aging at 700° throughout the bulk of the grains in the form of finely dispersed disk-shaped particles. Precipitation of γ′ phase (fcc lattice) in the form of globules and platelets is observed in the boundaries and intersections of grains and also near precipitates of primary β phase (Ni3Nb) with an orthorhombic lattice.

-

4.

The addition of 21.5% Co to the Ni-15Cr-10Nb alloy increases the dispersity and volume of precipitates of γ″ phase and also favors its transformation to β phase with an orthorhombic lattice in the process of overaging.

Similar content being viewed by others

Literature cited

B. G. Livshits and V. V. Osvenskii, "Structural transformations in Ni-Cr-Nb alloys", Izv. Akad. Nauk SSSR, Metall. Toplivo, No. 1, 139 (1962).

G. A. Sveshnikova, "Ni-Cr alloys with Nb," Metalloved. Term. Obrab. Met., No. 1, 29, (1966).

A. V. Smirnova et al., "Electron microscopic analysis of heat-resistant alloys KhN50MBVYu and KhN60MBVYu," in: New Methods of Testing Metals [in Russian], No. 79, Metallurgiya, Moscow (1972), p. 162.

J. Kirman, J. Iron Steel Inst.,207, No. 12, 1612 (1969).

J. Kirman and D. Warrington,Met. Trans.,1, No. 10, 2667 (1970).

D. Paulonis, J. Oblak, and D. Duvall, TASM,62, No. 3, 611 (1969).

W. Mitchell, Z. Metallk.,55, No. 10, 613 (1964).

L. V. Barseg'yan, N. M. Samarina, and I. B. Sidorova, "The process of decomposition in alloys based on Ni-Cr-Nb," in: Reports of the Tenth All-Union Conference on Electron Microscopy (Tashkent) [in Russian], Moscow (1976), p. 185.

W. Quist, R. Taggart, and D. Polonis,Met. Trans. 2, No. 3, 825 (1971).

B. G. Belov, S. N. Platova, and L. V. Barseg'yan, "New heat-resistant spring alloy 70NKhBMYu," Metalloved. Term. Obrab. Met., No. 2, 25 (1970).

L. N. Zimina, "Cobalt in heat-resistant nickel alloys," in: Special Steels and Alloys [in Russian], No. 1, Metallurgiya, Moscow (1972).

Additional information

I. P. Bardin Central Scientific-Research Institute of Ferrous Metallurgy. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 12, pp. 10–12, December, 1979.

Rights and permissions

About this article

Cite this article

Barseg'yan, L.V., Samarina, N.M. & Sidorova, I.B. Dispersion hardening of Ni-(Co)-Cr-Nb alloys. Met Sci Heat Treat 21, 903–906 (1979). https://doi.org/10.1007/BF00706622

Issue Date:

DOI: https://doi.org/10.1007/BF00706622