Conclusions

-

1.

The temperature fields of cylindrical bodies in the process of quenching in a moving or still liquid under excess pressure were calculated on the basis of a mathematical model proposed earlier.

-

2.

Analysis of the solutions obtained with the computer showed that during nucleate boiling the temperature on the surface of the cooled body changes negligibly, differing slightly from the saturation temperature of the cooling liquid, which makes it possible to control the boundary conditions by changing the pressure, i.e., slow down or speed up the transformation of austenite to martensite.

-

3.

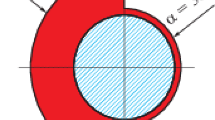

The change in the value of ξ0 can be neglected in simplified calculations, and it can be considered that the temperature on the surface is constant during nucleate boiling. This makes it possible to treat the experimental and theoretical data by means of the theory of normal thermal conditions. The data calculated by this method show that the generalized Biot number is a constant value that is independent of the dimensions of the cylinder and agrees with the experimental data.

-

4.

The generalized Biot number can be used only in calculating the cooling time of different bodies. In calculating the temperature fields it is necessary to solve nonlinear boundary problems of thermal conductivity.

Similar content being viewed by others

Literature cited

K. Z. Shepelyakovskii, Strengthening Machine Parts by Induction Hardening [in Russian], Mashinostroenie, Moscow (1972), p. 156.

K. Z. Shepelyakovskii et al., “Induction hardening of roller bearings”, Metalloved. Term. Obrab. Met., No. 1, 17 (1974).

N. I. Kobasko, “Intensification of quenching processes in steel”, Metalloved. Term. Obrab. Met., No. 2, 64 (1970).

N. I. Kobasko, “Development and introduction of new methods of cooling of steel parts during quenching”, Informatsionnyi Listok UkrNIINTI, No. 9, Ser. 13 (1972).

N. I. Kobasko and D. M. Kostanchuk, “Calculating the cooling capacity of quenching liquids by using the characteristics of the boiling process”, Metalloved. Term. Obrab. Met., No. 10, 21 (1973).

N. I. Kobasko, “Thermal processes during quenching of steel”, Metalloved. Term. Obrab. Met., No. 3, 2 (1968).

V. I. Tolubinskii et al., “Correlation of data on heat transfer during boiling of liquids on the basis of internal characteristics of the process”, in: Thermophysics and Thermotechnics [in Russian], No. 23, Naukova Dumka, Kiev (1973) p. 3.

V. B. Kogan, V. M. Fridman, and V. V. Kafarov, Equilibrium between Liquid and Vapor [in Russian], Nauka, Moscow-Leningrad (1966), p. 642.

L. S. Tong, Boiling Heat Transfer and Two-Phase Flow, Krieger (1975).

M. A. Mikheev, Fundamentals of Heat Transfer [in Russian], Gosenergoizdat, Moscow-Leningrad (1956), p. 392.

P. P. Yushkov, “Approximate solution of the problem of nonsteady thermal conductivity by the method of finite differences,“ in: Transactions of the Institute of Power Engineering [in Russian], No. 6, Moscow (1958), p. 3.

M. E. Blanter, “Cooling rate during quenching and hardenability of steel”, Zavod. Lab.,15, No. 5 (1949).

A. B. Vargaftik (editor), Handbook on the Thermophysical Properties of Substances [in Russian], Gosénergoizdat, Moscow-Leningrad (1956) p. 367.

N. I. Kobasko, “Self-regulating thermal processes,“ in: Heat and Mass Transfer [in Russian], Vol. 8, Nauka i Tekhnika (1968).

V. I. Fedorov and N. I. Kobasko, “Thermal processes during quenching of steel”, Metalloved. Term. Obrab. Met., No. 1, 66 (1970).

G. M. Kondrat'ev, Normal Thermal Conditions [in Russian], GITTL, Moscow (1954), p. 408.

V. I. Fedorov and N. I. Kobasko, “Calculating the cooling time of a body of complex configuration during quenching”, Metalloved. Term. Obrab. Met., No. 4, 59 (1972).

Additional information

Institute of Technical Thermophysics, Academy of Sciences of the Ukrainian SSR. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 10, pp. 8–13, October, 1976.

Rights and permissions

About this article

Cite this article

Kobasko, N.I. Computer analysis of thermal processes during quenching of steel. Met Sci Heat Treat 18, 846–852 (1976). https://doi.org/10.1007/BF00705187

Issue Date:

DOI: https://doi.org/10.1007/BF00705187