Conclusions

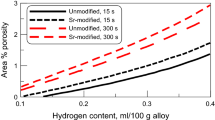

The service life of die-casting molds for aluminum alloys is greatest for steel 4Kh5MFS after quenching from 1010–1040°C and tempering at 560–570°C to hardness HRC 49–50.

Similar content being viewed by others

Literature Cited

Yu. A. Geller, Tool Steels [in Russian], Metallurgiya, Moscow (1975).

Yu. A. Geller, E. S. Golubeva, and A. I. Goncharova, "Modern steels for die-casting molds," Metalloved. Term. Obrab. Met., No. 1, 27 (1975).

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 10, pp. 66–67, October, 1978.

Rights and permissions

About this article

Cite this article

Itel'man, V.M. Effect of the hardness on the service life of die-casting molds for aluminum alloys. Met Sci Heat Treat 20, 861–862 (1978). https://doi.org/10.1007/BF00703793

Issue Date:

DOI: https://doi.org/10.1007/BF00703793