Conclusions

-

1.

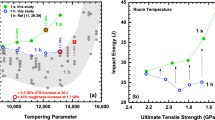

Plastic deformation after quenching and low-temperature tempering increases the ultimate tensile strength of steel 28Kh3SNMVFA, with retention of satisfactory ductility and fracture toughness.

-

2.

Low-temperature tempering after deformation leads to an additional increase in strength. This effect increases with the degree of deformation.

-

3.

The best combination of properties is obtained by quenching, tempering at 200°, 20% deformation, and tempering at 200°.

-

4.

The high strength of strain martensite is retained with tempering up to 500–550°.

-

5.

The strength of the deformed steel after brief tests at elevated temperatures (up to 500°) is higher than that of the quenched steel.

Similar content being viewed by others

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 9, pp. 26–29, September, 1978.

Rights and permissions

About this article

Cite this article

Vasil'eva, A.G., Komissarova, L.A. & Goryushin, V.V. Resistance of strain-hardened martensite to tempering. Met Sci Heat Treat 20, 718–721 (1978). https://doi.org/10.1007/BF00703750

Issue Date:

DOI: https://doi.org/10.1007/BF00703750