Conclusions

-

1.

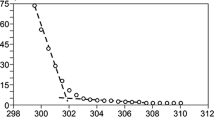

The model of the nonsteady temperature field during cooling in two or more media in succession makes it possible to calculate the temperature field in cylindrical forgings quenched in oil after rest in air. The largest difference in the experimental and calculated values of the temperatures of surface layers is ≤40°. Almost no differences in the experimental and calculated values of the cooling time were observed.

-

2.

The quenching time in oil may be shortened by 10–40 min due to rest in air for as long as 90 min, depending on the diameter of the forging.

-

3.

Rest in air reduces the maximum temperature gradient from the surface to the center of forgings. For forgings 200–900 mm in diameter the maximum temperature gradient is reduced most in the first hour at rest. For forgings larger than 900 mm in diameter the time at rest can be longer than 90 min.

-

4.

For forgings varying in diameter the time at rest is determined from the smallest diameter and the quenching time in oil from the largest diameter.

Similar content being viewed by others

Literature cited

Yu. A. Bashnin et al., Heat Treatment and Properties of Large Forgings [in Russian], Metallurgiya, Moscow (1973).

G. A. Pimenov et al., "Production of large forgings in the USSR and abroad," NIIIN-FORMTYaZhMASh, No. 12 (1973).

V. A. Gurenko et al., "Precise calculation of the temperature field in large forgings during quenching," Metalloved. Term. Obrab. Met., No. 10, 14 (1976).

A. L. Nemchinskii, Thermal Calculations of Heat Treatment [in Russian], Sudpromgiz, Leningrad (1953).

A. A. Shmykov, Heat Treatment Handbook [in Russian], Metallurgiya, Moscow (1961).

A. A. Astaf'ev and K. A. Ermakov, "Logical conditions for quenching large forgings of structural steel," Metalloved. Term. Obrab. Met., No. 4, 35 (1956).

A. A. Astaf'ev, "Heat treatment of large forgings," Metalloved. Term. Obrab. Met., No. 9, 2 (1973).

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 9, pp. 12–18, September, 1978.

Rights and permissions

About this article

Cite this article

Gurenko, V.A., Alekseev, P.E. Calculation of temperature fields in large forgings with quenching in oil and rest in air. Met Sci Heat Treat 20, 705–709 (1978). https://doi.org/10.1007/BF00703747

Issue Date:

DOI: https://doi.org/10.1007/BF00703747