Conclusions

-

1.

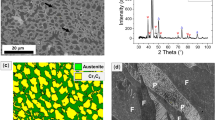

The addition of boron to high-carbon chromium facing alloys promotes formation of hypereutectic structures, increases the amount of the eutectic and changes its structure, alloys the basic phases and substantially increases their hardness, increases the structural and chemical heterogeneity of the facing metal and the zone of fusion due to formation of new phases and redistribution of alloying elements, and favors formation of martensite sections at the line of fusion.

-

2.

The wear resistance of dies and punches of peat briquetting presses operating under conditions of abrasive wear and high contact loads is highest with the addition of 2–2.5% B to high-carbon chromium facings. The service life of dies and punches with a facing of the U26Kh25R3 type is 3–4 times higher than that of punches faced with T-590 electrodes.

Similar content being viewed by others

Additional information

All-Union Scientific-Research Institute of Main Pipeline Construction. Moscow Branch of the All-Union Scientific-Research Institute of the Knitting Industry. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 12, pp. 48–50, December, 1978.

Rights and permissions

About this article

Cite this article

Grinberg, N.A., Mongait, I.A. Effect of boron on the phase composition and properties of facings during abrasive wear. Met Sci Heat Treat 20, 1016–1019 (1978). https://doi.org/10.1007/BF00703281

Issue Date:

DOI: https://doi.org/10.1007/BF00703281