Conclusions

-

1.

The best properties of the tungstenless steels are exhibited by 95Kh6M3F3T0.4 (V/C≅3) With V/C≅4 there is a reduction in secondary hardness and red hardness for this steel, but with a reduction in titanium content from 0.4 to 0.2% secondary hardness does not change, but red hardness decreases. It is confirmed that an increase in molybdenum content from 3 to 5% does not improve steel properties and therefore it is not rational.

-

2.

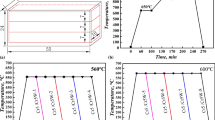

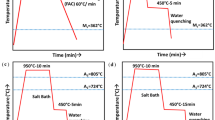

After oil quenching from 1225–1250°C and three-stage tempering at 540–550°C for 1 h each steel 95Kh6M3F3T0.4 is not surpassed by steel R6M5 in secondary hardness, red hardness, impact strength, and bending strength.

-

3.

The high properties of steel 95Kh6M3F3T0.4 are governed by the almost identical degree of solid solution alloying as with steel R6M5. The total content of carbide-forming elements in martensite after quenching these steels is 10–11%.

-

4.

With cooling at a rate from 3000 to 3°K/min steel 95Kh6M3F3T0.4 only experiences martensitic transformation. Isothermal decomposition of supercooled austenite for this steel commences with intense carbide precipitation, after which there is polymorphic γ → α-transformation.

Similar content being viewed by others

Literature cited

A. P. Gulyaev, Low-Alloy Tungsten and Molybdenum High-Speed Steels [in Russian], Mashgiz, Moscow-Leningrad (1941).

N. A. Minkevich, Low-Alloy High-Speed Steels [in Russian], Metallurgizdat, Moscow (1944).

K. A. Lanskaya, A. G. Rakhstadt, N. M. Suleimanov, and L. A. Roich, "Economically alloyed tool steel type 65Kh6M3F3BS", Stal', No. 10, 68–70 (1982).

K. A. Lanskaya, L. A. Roich, G. V. Vedyanskina, and A. G. Khakhalev, "Cutting tool of tungstenless steel 65Kh6M3F3SB," in: Advanced Production Experience in Automobile Building. Express Information, No. 11, 21–22 (1982).

K. A. Lanskaya, L. A. Roich, G. V. Vedyanskina, and A. G. Khakhalev, "Economically alloyed tungstenless steel for cutting tools", Avtomobil. Prom. No. 5, 18–21 (1984).

K. A. Lanskaya, L. A. Roich, E. F. Yakovleva, et al., "Phase composition of high-strength economically alloyed thermally stable steel", Izv. Akad. Nauk SSSR, Met., No. 5, 123–127 (1983).

K. A. Lanskaya, O. V. Basargin, A. G. Rakhstadt, and A. L. Roich, "Kinetics of super-cooled austenite decomposition in Cr-Mo-V steels", Metalloved. Term. Otrab. Met., No. 1, 3–6 (1983).

A. P. Gulyaev, I. K. Kupalova, and V. A. Landa, "Procedure and results of phase analysis for high-speed steels," Zavod. Lab., No. 3 (1965).

K. A. Lanskaya, A. G. Rakhstadt, N. M. Suleimanov, et al., "Properties of tungstenless steel for cutting tools", Stal', No. 1, 73–75 (1984).

Additional information

I. P. Bardin Central Scientific-Research Institute of Ferrous Metallurgy (TsNIIChERMET), N. É. Bauman Higher Technical School, Special Design Office of Textile Machinery ‘Kristall’, Academy of Sciences of the Azerbaijan SSR. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 5, pp. 43–47, May, 1988.

Rights and permissions

About this article

Cite this article

Lanskaya, K.A., Rakhshtadt, A.G., Suleimanov, N.M. et al. Effect of alloying on the properties and heat treatment of low-alloy tungstenless high-speed steel 95Kh6M3F3T. Met Sci Heat Treat 30, 370–375 (1988). https://doi.org/10.1007/BF00701049

Issue Date:

DOI: https://doi.org/10.1007/BF00701049