Conclusions

-

1.

Repeated stepwise deformation of steels 40 and 40G with various degrees of necking in the 1150–650°C interval retains the effect of hereditary hardening both after hot plastic deformation and during subsequent high-frequency heating to 860°C for quenching.

-

2.

HTMSH and knurling of the sprocket wheels in combination with heat treatment by high-frequency-current heating leads to the formation of a fine-disperse structure of the martensite and its decomposition products during self-tempering; this contributes to a 15–20% increase in the mechanical properties.

-

3.

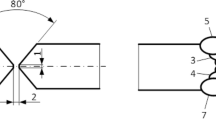

The following regime is recommended for the HTMSH of sprocket-wheel-type components of complex shape: HFC heating of blanks at a rate of 50–150 deg/sec to 1150–1180°C at a depth to 15 mm, subsequent hot plastic repeated stepwise deformation in the 1150–850°C interval with a total necking ε=70% at strain rates of 2.5–4.5 mm/sec, and quenching from the 840–850°C end temperature of deformation with water-spray cooling (3–8 sec), which ensures self-tempering of the component at 350–380°C.

-

4.

The introduction of high-temperature thermomechanical surface hardening at the "Rossel'mash” plant and the Ryazan' Combine plant in lieu of milling and heat treatment with HFC heating made it possible to increase the quality and service life of steel 40 and 40G chain-drive sprocket wheels for agricultural machinery, reduce the number of operations in the technological cycle, increase productivity, and reduce metal and tool consumption, as well as realize an annual savings of 72,510 rubles.

Similar content being viewed by others

Literature cited

P. I. Rusin et al., "High-temperature thermomechanical hardening of chain-drive sprocket wheels subject to induction heating,” in: Application of High-Frequency Currents in Electrothermics [in Russian], Mashinostroenie, Leningrad (1973), p. 148.

M. L. Bernshtein, Thermomechanical Hardening of Metals and Alloys [in Russian], Vol. 2, Metallurgiya, Moscow (1968), p. 696.

A. D. Stepanovich and E. A. Sukhorukova, "Characteristic features of the fine texture of steel 40G after high-temperature thermomechanical surface hardening,” in: Proceedings of the Rostov Institute of Agricultural Machine Building: Progressive Methods of Heat Treatment in Tractor and Agricultural Machine Building [in Russian], Rostovskiina-Donu Institut Sel'skokhozyaistvennogo Mashinostroeniya, Rostov-on-Don (1978), p. 148.

Additional information

Rostov-on-Don Institute of Agricultural Machine Building. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 2, pp. 15–18, February, 1982.

Rights and permissions

About this article

Cite this article

Stepanovich, A.D., Stepanovich, V.A. Properties of medium-carbon steels after thermomechanical hardening with repeated deformation. Met Sci Heat Treat 24, 92–96 (1982). https://doi.org/10.1007/BF00700930

Issue Date:

DOI: https://doi.org/10.1007/BF00700930