Conclusions

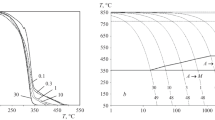

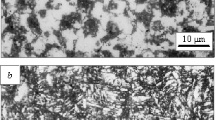

With heat treatment to a given hardness, high-speed steels manufactured by atomization have higher mechanical properties than standard steel of similar composition due to the homogeneous fine-grained structure and even distribution of finely dispersed carbide phase. These steels should be quenched from temperatures 20–30° lower than for standard steels.

Similar content being viewed by others

Literature cited

J. E. Dalis, "High-speed steels obtained by P/M methods," in: Powder Metallurgy of Materials for Special Purposes [Russian translation], Metallurgiya, Moscow (1977), p. 300.

E. Haberling, Stahl Eisen,95, No. 10, 454 (1975).

A. Krzanowski and A. Pugacewicz, Metaloznawstwo i Obrob. Ciepl., No. 27, 8 (1977).

Additional information

Moscow Automobile Factory. NPO Tulachermet. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 9, pp. 54–56, September, 1980.

Rights and permissions

About this article

Cite this article

Goryushina, M.N., Gavrikov, N.N., Bolonkina, I.B. et al. Heat treatment and properties of high-speed steel 10R6M5-MP produced by atomization and hot extrusion. Met Sci Heat Treat 22, 691–693 (1980). https://doi.org/10.1007/BF00700701

Issue Date:

DOI: https://doi.org/10.1007/BF00700701