Conclusions

-

1.

After high-speed hardening of spring steels, the martensite is characterized by smaller size of crystals, predominantly of twinned type, high level of distortions, higher content of carbon but with its greater concentrational nonuniformity than after ordinary hardening with furnace heating.

-

2.

A decisive influence on the properties of spring steels, in particular on the resistance to small plastic deformations (elastic limit σ0.005), is exerted by residual austenite if contained in their structure, therefore after subzero treatment of hardened steel σ0.005 greatly increases.

-

3.

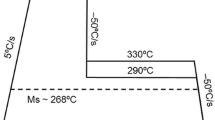

After high-speed hardening and subsequent high-speed tempering the maxima of the elastic and fatigue limits are attained with equal tempering time, viz., 3 sec, because of the decisive influence of the development of processes of microplastic deformations on these properties. To attain maximal relaxation resistance, greater stability of the structure and correspondingly longer high-speed tempering is required.

Similar content being viewed by others

Literature cited

V. N. Gridnev, Yu. Ya. Meshkov, S. P. Oshkaderov, and V. I. Trefilov, Physical Fundamentals of the Thermoelectric Strengthening of Steel [in Russian], Naukova Dumka, Kiev (1973).

V. N. Gridnev, S. P. Oshkaderov, Yu. Ya. Meshkov, and N. F. Chernenko, The Technological Fundamentals of the Thermoelectric Treatment of Steel [in Russian], Naukova Dumka, Kiev (1977).

I. N. Kidin, Physical Fundamentals of the Thermoelectric Treatment of Metals and Alloys [in Russian], Metallurgiya, Moscow (1969).

V. N. Gridnev and S. P. Oshkaderov, "Application of high-speed heat treatment for increasing the structural strength of steels," Metalloved. Term. Obrab. Met., No. 11, 19–22 (1987).

S. Ya. Grilikhes, R. I. Mishkevich, A. G. Rakhshtadt, and A. M. Rabyshev, Thermoelectrochemical Treatment of Elastic Elements [in Russian], Mashinostroenie, Moscow (1978).

A. G. Rakhshtadt and M. A. Shtremel', "Method of determining the elastic limit of specimens of thick sheet," Zavod. Lab.,26, No. 6, 64–66 (1960).

Yu. V. Kal'ner and V. G. Prokoshkina, "The stability of the structure of carbon steels after laser heat treatment," in: Methods of Increasing the Structural Strength of Metallic Materials [in Russian], MDNDP (1988), pp. 102–112.

Additional information

N. É. Bauman Moscow State Technical University. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 7, pp. 57–63, July, 1990.

Rights and permissions

About this article

Cite this article

Rakhshtadt, A.G., Dumanskii, I.O. & Tikhomirova, O.Y. Structure and properties of carbon-containing spring steels after high-speed hardening and tempering. Met Sci Heat Treat 32, 541–550 (1990). https://doi.org/10.1007/BF00700330

Issue Date:

DOI: https://doi.org/10.1007/BF00700330