Conclusions

-

1.

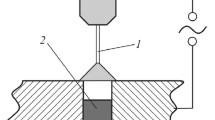

Formation of a Al−Cu-joint structure made by butting contact fusion welding occurs by a soldering mechanism, i.e., welding with development in the joint of hypereutectic alloy.

-

2.

The structure of the transition zone of joints made by friction welding consists of a solid solution of copper in aluminum with a very small amount (∼1.5%) θ-phase which provides quite high strength properties for these joints.

Similar content being viewed by others

Literature cited

A. E. Vol, Structure and Properties of Binary Metal Systems, Vol. 1 [in Russian], Fizmatgiz, Moscow (1959).

Additional information

ZIL Factory Higher Technical School. ZIL Production Association. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 12, pp. 34, December, 1990.

Rights and permissions

About this article

Cite this article

Mozhaiskaya, T.M., Chekanova, N.T. Structure and properties of welded aluminum-copper joints. Met Sci Heat Treat 32, 938–939 (1990). https://doi.org/10.1007/BF00700088

Issue Date:

DOI: https://doi.org/10.1007/BF00700088