Conclusions

-

1.

The magnitude and sign of residual stresses of the first kind vary several times both near the surface and in the volume of the specimen as a result of thermal cycling.

-

2.

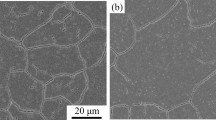

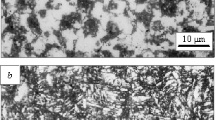

Thermal cycling leads to variation in block dimensions and dislocation density.

-

3.

The maximum limited longevity of steel 3KhM3F is observed at the highest residual compressive stresses and dislocation density.

-

4.

Use of certain types of technological treatments (PME, HTMT, and their combinations) lead to an increase in specimen longevity; this enables us to suggest the promising nature of these methods of treatment for the hardening of hot-stamping dies.

Similar content being viewed by others

Literature cited

S. S. Gorelik, L. N. Rostorguev, and Yu. A. Skakov, Radiographic and Electron-Microscope Analysis [in Russian], Metallurgiya, Moscow (1970).

V. N. Polyakov, A. A. Kisurin, V. I. Fateev, and A. S. Dancheev, "A method for the thermal-fatigue testing of die steels," in: Investigations into the area of Plasticity and the Pressure Treatment of Metals [in Russian], No. 2, Tula Polytechnic Inst. (1974), pp. 113–119

Additional information

Tula Polytechnic Institute. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 3, pp. 29–31, March, 1985.

Rights and permissions

About this article

Cite this article

Kisurin, A.A., Revyakina, E.V., Fateev, V.I. et al. Effect of cyclic temperature effects and certain methods of hardening on the residual-stress distribution in steel 3Kh3M3F. Met Sci Heat Treat 27, 202–204 (1985). https://doi.org/10.1007/BF00699652

Issue Date:

DOI: https://doi.org/10.1007/BF00699652