Conclusions

-

1.

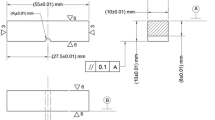

Ferromagnetic carbides of the cementite type are present in the steel after quenching (without tempering) and after tempering at temperatures below 620° for 1 h. Carbides of the cementite type have the shape of thin platelets with a length up to 100 Å (tempering at 200°), up to 1000 Å (tempering at 350°), and up to 2000 Å (tempering at 500° and higher).

-

2.

MC secondary carbides (VC) are precipitated in the process of tempering at temperatures ≥540°. The electrochemical properties of these dispersed carbides and MC carbides differ greatly after quenching or annealing. The properties become similar with increasing tempering temperatures.

-

3.

M2C secondary carbides and chromium carbides are precipitated during tempering at 560–580° and higher, and M6C carbides with tempering above 640–650°. No preferential precipitation of special carbides on cementite particles or the boundaries of martensite crystals, twins, or other lattice defects was observed.

-

4.

Precipitation of special carbides is accompanied by a reduction of the austenite and martensite lattice constant. Formation of M6C carbides is observed after almost complete isothermal transformation of retained austenite and reduction of the lattice constant of α phase to a value close to that obtained after annealing.

Similar content being viewed by others

Literature cited

É. T. Shapoval et al., “Use of the potentiostatic method to study high-speed steels and alloys”, Zavod. Lab., No. 2, 145 (1980).

L. I. Baranova, Methodological Characteristics of Phase Chemical Analysis of High-Speed Steels. Express Information: Physicochemical Analysis of Steels and Alloys in Ferrous Metallurgy Plants [in Russian], Chermetinformatsiya, Moscow (1979), p. 13.

V. A. Kazakovtseva and I. K. Kupalova, “Electron microscopic study of transformations during tempering of steel R6M5,” in: Use of Transmission and Scanning Electron Microscopy in Metal Science [in Russian], Obshchestvo Znanie RSFSR, Moscow (1976), p. 117.

L. A. Alekseev, I. K. Kupalova, and R. B. Levi, “Possibility of using Mössbauer spectroscopy for phase analysis of complex alloy steels,” in: Main Trends in the Development of Analytical Controls and Methods of Physicochemical Analysis in Ferrous Metallurgy Plants [in Russian], Chermetinformatsiya, Zaporozhe (1975), p. 35.

R. Leveque and A. Condylis, Mem. Scient. Rev. Metallurg.,68, No. 2, 87 (1971).

R. Leveque, 16 Colloque de Metallurgie, Saclay, Juin (1973), p. 735.

A. N. Popandopulo and G. Yu. Novikova, “Transformations during high-temperature quenching of high-speed steel R6M5K5,“ Metalloved. Term. Obrab. Met., No. 8, 36 (1978).

A. P. Gulyaev, “Mechanism of structural transformations during tempering of high-speed steels,” Metallurg., No. 12, 73 (1936).

G. Barreau, G. Cizeron, and O. Jacura, Bul. Cercle Etud. Metaux, Num. Spec., 317 (1975).

N. Bugoevich and N. Khobbobich-Simovich, Glasnik Khim. Drusht., Belgrade,37, No. 7–8, (1972), p. 399.

A. P. Gulyaev, Properties and Heat Treatment of High-Speed Steel [in Russian], Mashgiz, Moscow-Lengingrad (1939).

Yu. A. Geller, Tool Steels [in Russian], Metallurgiya, Moscow (1975), p. 354.

K. Kuo, J. Iron Steel Inst., No. 174, 223 (1953).

T. Sato, T. Nisizawa, and K. Murey, J. Iron Steel Inst. Jpn.,45, No. 4, 409 (1959).

T. Mukherjee, ISI Publ.,126, 80 (1970).

T. Malkiewice, Metallurgie,3, No. 1, 1 (1962).

E. Horn, DEW Techn. Ber.,13, No. 3, 171 (1973).

I. K. Kupalova and E. M. Stepnov, “Transformations occurring in the process of heating quenched high-speed steels,” Fiz. Met. Metalloved.,30, No. 5, 1115 (1970).

V. A. Landa, “High-temperature investigation of secondary martensitic transformation during tempering of tool steels,” in: Physical Methods of Investigation and Control of the Structure of Tool Steels [in Russian], Mashgiz, Moscow (1963), p. 143.

J. Aswegen and R. Honeycombe, Acta Met.,10, No. 3, 262 (1962).

D. Warrington, H. Harding, and R. Honeycombe, “Electron microscope 1964,” in: Transactions of the Third European Periodic Conference [in Russian], Praga (1964), Vol. A, p. 225.

T. Malkiewicz and Z. Bojarski, Prace Inst. Hutn.13, No. 6, 311 (1961/1962).

S. Koshiba, S. Kimura, and H. Harada, J. Jpn. Inst. Met.,24, No. 7, 437 (1960).

É. T. Shapovalov et al., “Possibility of applying the potentiodynamic method to the technological problem of manufacturing tools of high-speed steels,” in: Transactions of the All-Union Scientific-Research Tool Institute [in Russian], Moscow (1975), p. 82.

E. Haberling, A. Rose, and H. Weigand, Stahl Eisen,93, No. 14, 645 (1973).

L. Paganini, V. Bulckaen, and R. Baronti, La Metal. Italiana, No. 11, 617 (1974).

V. G. Permyakov et al., “Magnetometric analysis of the transformation of retained austenite in high-speed steel R12,” Izv. Vyssh. Uchebn. Zaved., Chern. Metall. (1974).

Yu. S. Dvoryadkin and V. I. Izotov, “Electron microscopic study of the structure of steel R18,” Metalloved. Term. Obrab. Met., No. 1, 37 (1972).

E. Bridge, N. Gunvant, and N. Maniar, Met. Trans.,2, No. 8, 2209 (1971).

I. K. Kupalova, “Change in the properties of high-speed steel R9 as the result of prolonged tempering,” in: Metalworking and Monitoring-Measuring Instruments [in Russian], No. 9, NIIMASh, Moscow (1970), p. 17.

Additional information

All-Union Scientific-Research Tool Institute. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 7, pp. 55–60, July, 1980.

Rights and permissions

About this article

Cite this article

Kupalova, I.K. Transformations in high-speed steels during tempering. Met Sci Heat Treat 22, 522–527 (1980). https://doi.org/10.1007/BF00693598

Issue Date:

DOI: https://doi.org/10.1007/BF00693598