Conclusions

-

1.

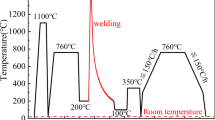

Powder metallurgy tungsten-free ROM2F3-MP steel possesses high technological properties (hot plasticity, grindability) with practically the same cutting capacity and heat resistance as the standard R6M5 steel.

-

2.

The use of powder metallurgy high-speed ROM2F3-MP steel instead of standard R6M5 steel makes it possible to save 60 kg of scarce tungsten and 20–30 kg of scarce molybdenum per ton of steel.

Similar content being viewed by others

Literature cited

A. I. Lyapunov and A. I. Aparova, The Present State and Means of Development of the Production of High-Speed Steels in the USSR and Abroad, "Metal Science and Heat Treatment" Series [in Russian], No. 2, Tsent. Nauch.-Issled. Inst. Inf. i Tekh.-Ékon. Issled. Chern. Met., Moscow (1982).

N. A. Minkevich, Low-Alloy High Speed Steels [in Russian], Metallurgizdat, Moscow (1944).

A. P. Gulyaev, Low-Alloy Tungsten and Molybdenum High-Speed Steels [in Russian], Mashgiz, Moscow-Leningrad (1941).

E. Houdremont and H. Schrader, Stahl Eisen, No. 12 (1937).

Yu. A. Geller, "Technological properties of high-speed steels," Stank. Instrum., No. 7–8, 10–16 (1944).

A. I. Lyapunov, F. I. Zhdanov, and N. A. Tarakhnova, The Use of Powder Metallurgy High-Speed Steels in Tool Production [in Russian], Nauch.-Issled. Inst. Inf. Mashinostr., Moscow (1983), p. 39.

G. G. Mukhin, V. A. Gorelov, and L. P. Korotkova, "A sintered high-speed steel without tungsten," Vestn. Mashinostr., No. 9, 45–46 (1981).

A. Kasak and E. I. Dulis, Powder Met.,21, No. 2, 114–123 (1978).

A. N. Popandopulo, L. N. Gerashchenko, Z. S. Bystrova, and G. P. Anastasiadi, "The phase composition and structure of atomized powders of high-vanadium tungsten-molybdenum high-speed steel," Poroshk. Metall., No. 12, 5–7 (1976).

G. G. Mukhin and L. P. Korotkova, "The nature of the high hardness of atomized high-speed steels," Metalloved. Term. Obrab. Met., No. 10, 8–11 (1982).

A. K. Petrov, I. S. Miroshnichenko, V. V. Parabin, et al., "An investigation of the crystallization of metal powder produced by atomization of the liquid phase," Poroshk. Metal., No. 1, 16–20 (1973).

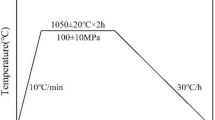

V. B. Akimenko A. A. Galkin, I. Ya. Kondratov et al., Hot Pressing (Handbook) [in Russian], Inst. Probl. Materialoved. Akad. Nauk UkrSSR, Kiev (1973)

H. Sauer, J. Püber, and R. Auer, "Ereugungs versuche von Schnellarbeitsstahle aus Pulver durch Stangpreseen," Berg und Hütten, männische Monatshefte,120, No. 11, 528–537 (1975).

Yu. A. Geller, Tool Steels [in Russian], Metallurgiya, Moscow (1983).

Additional information

I. P. Bardin Central-Scientific Research Institute for Ferrous Metallurgy. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 5, pp. 37–43, May, 1985.

Rights and permissions

About this article

Cite this article

Gulyaev, A.P., Sergienko, L.P. & Tolkacheva, E.P. Structure and properties of power metallurgy tungsten-free ROM2F3-MP high-speed steel. Met Sci Heat Treat 27, 356–364 (1985). https://doi.org/10.1007/BF00693376

Issue Date:

DOI: https://doi.org/10.1007/BF00693376