Conclusions

-

1.

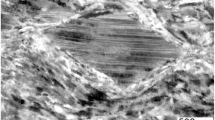

Deformation of Hadfield steel commences by a dislocation mechanism which rapidly changes into a twinning mechanism for austenite which starts by one, and then by several, twinning systems {111} 〈112〉.

-

2.

Mechanical twinning hinders dislocation movement, thus strengthening the steel, and it also leads to relaxation of internal stresses in the steel, as a result of which its ductility increases, and this is a basic reason for the high tendency of Hadfield steel towards strengthening during deformation.

-

3.

In vacuum-melted Hadfield steel deformation twins have a strongly curved shape, and this may be a reason for the higher mechanical properties compared with those of open-melted steel.

Similar content being viewed by others

Literature cited

R. Hadfield, J. Iron Steel Inst., No. 34, 41 (1888); E. Gudremont, Special Steels [in Russian], Metallurgiya, Moscow (1966).

A. P. Gulyaev, Metal Science [in Russian], Metallurgiya, Moscow (1977).

Yu. M. Lakhtin, Metal Science and Heat Treatment of Metals [in Russian], Metallurgiya, Moscow (1976).

G. Colleete, "Contribution a l'etude austenite a 12% Mn," Rev. Metall., No. 54, 433 (1957).

O. O. Lambakakhar and Yu. I. Paskal', "Dislocation structure and strain hardening of high-manganese steel", Izv. Vyssh. Uchebn. Zaved., Fiz., No. 7, 26 (1973).

C. White and R. Honeycombe, "Structural changes during the deformation of high-purity iron-manganese-carbon alloys", J. Iron Steel Inst.,200, No. 6, 457 (1962).

V. S. Litvinov, S. D. Karakishev, and V. S. Tsurin, "Mössbauer studies of iron-manganese carbide of austenite", Fiz. Met. Metalloved.,47, No. 2, 352 (1977).

I. I. Bogachev, L. G. Korshunov, and M. S. Khadyev, "Study of strengthening and structural transformations for steel 110G13 during wear", Fiz. Met. Metalloved.,43, No. 2, 380 (1977).

L. P. Strok, K. I. Krasikov, and N. K. Shaurova, "Study of the fine structure of steel 110G13L after high-speed deformation", Izv. Vyssh. Uchebn. Zaved., Fiz., No. 7, 72 (1973).

I. Ya. Georgieva, A. A. Gulyaev, and E. Yu. Kondrat'eva, "Deformation twinning and mechanical properties of austenite manganese steels", Metalloved. Term. Obrab. Met., No. 8, 56 (1976).

D. Pashley and M. Stowell, "Electron microscopy and diffraction of twin structures in evaporated films", Philos. Mag.,8, No. 94, 1605 (1963).

I. Ya. Georgieva, "High-strength steels and ductility induced by martensitic transformation," in: Metal Science and Heat Treatment of Metals. Results of Science and Technology, VINITI,16, 69 (1982).

A. Kelly and G. Groves, Crystallography and Defects in Crystals [Russian translation], Mir, Moscow (1974).

M. L. Bernshtein and V. A. Zaimovskii, Mechanical Properties of Metals [in Russian], Metallurgiya, Moscow (1979).

J. P. Hirth and J. Lothe, Theory of Dislocation, McGraw-Hill (1967).

V. S. Zharinova, I. Ya. Georgieva, A. A. Gulyaev, and A. G. Vasil'eva, "Effect of treatment method on the strengthening mechanism and properties of austenitic steels of the systems Fe Mn−V−C and Fe−Mn−Cr−C", in: Improvement in Quality, Reliability and Life of Articles Made of Structural, Heat-Resistant, and Tool Steels and Alloys [in Russian], LDNTP (1980).

T. P. Vasechkina, V. G. Pushin, A. N. Uksusnikov, and A. I. Uvarov, "Structure and mechanical properties of metastable chromium-manganese steels after deformation in tension", Fiz. Met. Metalloved.,46, No. 5, 963 (1978).

Additional information

I. P. Bardin All-Union Institute of Ferrous Metallurgy. Scientific-Research Institute of Machine Building and Metal Treatment (NIIMASh). Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 6, pp. 14–18, June, 1985.

Rights and permissions

About this article

Cite this article

Gulyaev, A.A., Tyapkin, Y.D., Golikov, V.A. et al. The fine structure of Hadfield steel. Met Sci Heat Treat 27, 411–415 (1985). https://doi.org/10.1007/BF00693279

Issue Date:

DOI: https://doi.org/10.1007/BF00693279