Conclusions

-

1.

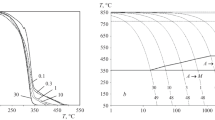

Quenching from 820°C, usually recommended for maraging steels, does not make it possible to obtain the optimal properties for steel N14Kh5M3TYu. The highest ductility and toughness are attained by quenching from 950–980°C.

-

2.

The optimal combination of strength, ductility, and toughness results from quenching from these temperatures and aging at 480–520°C.

-

3.

Repeated aging results in an additional increase of the strength beginning at temperatures of 300°C and continuing up to the primary aging temperature (480–520°C), which may be due to some differences in the kinetics and composition of precipitates that depend on the original condition of the solid solution before aging.

Similar content being viewed by others

Literature cited

D. Peters, Trans. AIME,243, No. 12 (1967).

D. Gorn, J. of Metals,16, No. 10 (1964).

M. D. Perkas and V. M. Kardonskii, High-Strength Maraging Steels [in Russian] (1970).

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 3, pp. 11–14, March. 1972.

Rights and permissions

About this article

Cite this article

Prokhorov, P.A., Larichev, Y.A. & Goncharov, A.F. Mechanical properties of steel N14Kh5M3TYu after heat treatment. Met Sci Heat Treat 14, 197–199 (1972). https://doi.org/10.1007/BF00690761

Issue Date:

DOI: https://doi.org/10.1007/BF00690761