Conclusions

-

1.

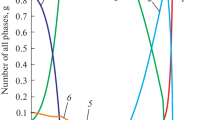

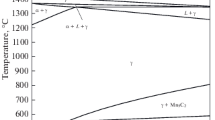

The addition of 2–10% Mo to martensitic steels 13Cr−14Co−6Ni and 9Cr−14Co−6Ni increases the amount of retained austenite. Steels with 13 and 9% Cr become almost completely austenitic with 2 and 10% Mo respectively. Intermetallic phase of the Fe2Mo type is formed, the temperature-time range in which it exists being considerably broader in steels with 13% Cr (at the same molybdenum concentration).

-

2.

Raising the molybdenum content of the steels investigated increases the strength slightly and lowers the toughness after quenching due to formation of Fe2Mo in grain boundaries.

-

3.

Tempering of martensitic steels with 9% Cr at 500° leads to a substantial increase in strength, the effect increasing with the molybdenum content from 2 to 6% Mo. The increase in the strength of the steel with 9% Cr to 210 kg/mm2 after tempering is evidently due to the formation of finely dispersed intermetallic R phase.

Tempering at 500° does not induce any increase in the strength of steels with 13% Cr and 2–10% Mo, which have an austenitic structure.

-

4.

Steels of the 9Cr−14Co−6Ni system alloyed with 2–6% Mo can be used as the basis for the development of high-strength corrosion resistant steels retaining their toughness at low temperatures.

Similar content being viewed by others

Literature cited

S. Florren and R. Decker, TASM,55, No. 1, 518 (1962).

M. D. Perkas and V. M. Kardonskii, High-Strength Maraging Steels [in Russian], Metallurgiya, Moscow (1970).

R. Bastien and G. Pomey, Compt. Rend.,239, 1636 (1954).

E. Z. Vintaikin and V. Yu. Kolontsov, “Aging of Fe−Cr alloys,” Fiz. Metal. Metalloved.,26, No. 2, 282 (1968).

F. Thompson and D. West, J. Iron Steel Inst.,210, No. 9, 691 (1972).

N. F. Lashko et al., “Phase composition, structure, and properties of maraging steel Kh14K9N6M5,” Metal. i Term. Obrabotka Metal., No. 10, 39 (1974).

Additional information

I. P. Bardin Central Scientific-Research Institute of Ferrous Metallurgy. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 11, pp. 63–65, November, 1975.

Rights and permissions

About this article

Cite this article

Shlyamnev, A.P., Sorokina, N.A. Phase composition and properties of maraging steels alloyed with molybdenum. Met Sci Heat Treat 17, 973–976 (1975). https://doi.org/10.1007/BF00679394

Issue Date:

DOI: https://doi.org/10.1007/BF00679394