Conclusions

-

1.

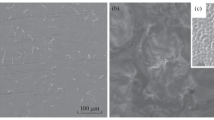

The finely dispersed structure of unmodified Silumin alloys formed during rapid cooling is a degenerate eutectic due to the independent nucleation and growth of phases resulting from the suppression of diffusion processes with large supercooling.

-

2.

Additions of surface-active elements to Silumin alloys suppress the nucleation centers of eutectic silicon and slow down their growth in the process of further transformations.

-

3.

The leading phase during solidification of the modified eutectic is aluminum, which outstrips the growth of silicon crystals and blocks them from the liquid. Due to the periodic supersaturation of the liquid with silicon, the silicon particles are wedged out at the solidification front and are immediately surrounded by aluminum phase.

Similar content being viewed by others

Literature cited

J. Edwards and R. Archer, Chem. and Met. Eng.,31, 504–508 (1924).

M. V. Mal'tsev, Modification of the Structure of Metals and Alloys [in Russian], Metallurgiya, Moscow (1964).

S. Ghosh and V. Kondic, Modern Casting,43, 2, 17–25 (1963).

V. Davies and J. West, J. Inst. Metals,92, 6, 175–180 (1964).

J. Bell and W. Winegard, J. Inst. Metals,94, 226–227 (1966).

C. Ransley and H. Neufeld, J. Inst. Metals,78, 25–46 (1950–51).

A. Gwyer and H. Phillips, J. Inst. Metals,26, 283 (1926).

B. Thall and B. Chalmers, J. Inst. Metals,77, 1, 79 (1950).

R. Plumb and J. Lewis, J. Inst. Metals,86, 8, 393 (1957–58).

W. A. Tiller, "Multiphase solidification," in: Liquid Metals and Their Solidification [Russian translation], Gostekhizdat, Moscow (1962), pp. 335–340.

G. Chadwick, Progress in Mater. Science,12, 2, 97 (1963).

C. Kim and R. Heine, J. Inst. Metals,92, 11, 367–376 (1963–64).

M. B. Gokhshtein and L. S. Vasil'eva, "Mechanism of modification of Silumin alloys," Metal. i Term. Obrabotka Metal.,7, 42–44 (1970).

J. Curran, Chem. and Mat. Eng.,27, 360–361 (1922).

E. Schulz, Z. Metallk.,39, 123–128 (1948).

E. A. Boom, Nature of Modification of Silumin Alloys [in Russian], Metallurgiya, Moscow (1972).

P. A. Parkhutik and M. Z. Lubenskii, "Effect of solidification conditions on the structure of aluminum—silicon alloys," Metal. i Term. Obrabotka Metal., 9, 68–69 (1972).

I. S. Miroshnichenko and A. Ya. Andreeva, "Degeneration of eutectic structures," in: Phase Transformations [in Russian], Naukova Dumka, Kiev (1970), pp. 169–175.

Additional information

Physicotechnical Institute, Academy of Sciences, Belorussian SSR. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, Vo. 1, pp. 66–68, January, 1974.

Rights and permissions

About this article

Cite this article

Parkhutik, P.A., Kalashnik, L.D. & Solov'ev, S.P. Solidification mechanism of modified silumins. Met Sci Heat Treat 16, 71–74 (1974). https://doi.org/10.1007/BF00679209

Issue Date:

DOI: https://doi.org/10.1007/BF00679209