Conclusions

-

1.

The wear resistance is highest for alloys with both chromium and titanium. The optimal amount of carbon depends on the titanium content. It should be above stoichiometric.

-

2.

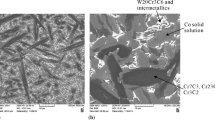

The wear resistance of high-carbon Cr−Ti alloys depends on the structural condition of the matrix and the total quantity and type of the carbide phase.

-

3.

The abrasive wear resistance is highest for alloys U20Kh6T4M and U25Kh6T4M with a structure of austenite-carbide or austenite-martensite-carbide, with at least 30% retained austenite. The best results are obtained when the carbide phase is the strong and hard TiC, in combination with carbides M7C3 and M23C6.

Similar content being viewed by others

Literature cited

G. I. Ivantsov and A. G. Shchulepnikova, "Effect of hardening procedure on abrasive wear resistance of iron alloys," Izv. Vuzov, Fizika, 7, 16–19 (1967).

L. S. Livshits, N. A. Grinberg, and É. G. Kurkumelli, Fundamentals of Alloying Facing Metals [in Russian], Mashinostroenie, Moscow (1969).

V. S. Popov, N. N. Brykov and N. S. Dmitrichenko, Wear Resistance of Molds for Production of Refractory Bricks [in Russian], Metallurgiya, Moscow (1971).

V. A. Ul'yanov, "Cast wear resistant alloys with boron and titanium additions," in: Increasing the Wear Resistance and Service Life of Machines [in Russian], Vol. 1, Izd. AN Ukrainian SSR, Kiev (1960), pp. 232–237.

A. F. Fereshchenko et al., "Apparatus for determining the wear resistance of facing metals," in: Abrasive Wear and Increasing the Wear Resistance of Parts by Means of Facing and Spray Coating [in Russian], Ukr. Izd. Obshchestva Znanie, Kiev (1970), pp. 45–47.

A. P. Gulyaev, Heat Treatment of Steel [in Russian], Mashgiz, Moscow (1960), p. 245.

G. R. Comstock, Titanium in Cast Iron and Steel [Russian translation], IL, Moscow (1956), p. 37.

S. A. Golovanenko et al. "Wear resistance of steels for bimetallic parts of farm machines," Metal. i Term. Obrabotka Metal., 7, 47–50 (1969).

Additional information

E. O. Paton Institute of Electric Welding. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 1, pp. 46–48, January, 1974.

Rights and permissions

About this article

Cite this article

Ryabtsev, I.A., Golovashchuk, A.I. & Frumin, I.I. Structure and wear resistance of high-carbon Cr−Ti alloys. Met Sci Heat Treat 16, 46–48 (1974). https://doi.org/10.1007/BF00679201

Issue Date:

DOI: https://doi.org/10.1007/BF00679201