Conclusions

-

1.

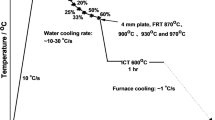

Raising the initial rolling temperature from 1050–1100 to 1200–1250° increases the strength characteristics due to the solution of carbonitrides; therefore, the effect of the increase in strength is stronger in the steel alloyed with vanadium and niobium, and is hardly manifest in the steel not containing these elements.

-

2.

Lowering the final rolling temperature from 950 to 700° leads to higher strength characteristics, particularly final rolling at 700°.

-

3.

Lowering the final rolling temperature lowers the ductile-brittle transition temperature (T50), i.e., increases the resistance to brittle fracture. However, the work of crack propagation decreases in this case, i.e., the resistance to ductile fracture.

-

4.

The increase in strength and lower ductile-brittle transition temperature when the final rolling temperature is lowered are due to grain refining. However, the work of crack propagation decreases in this case (a p) and also the notch toughness at −40°. A final rolling temperature of 800° produces the best combination of mechanical properties.

-

5.

The high values of the strength, ductility, and toughness in combination with a very low carbon equivalent lead us to consider low-pearlitic steels as promising materials for welded structures and materials requiring good weldability and resistance to fracture. Controlled rolling makes it possible to control the properties of these steels within wide limits by changes in the strength, ductility, and toughness, depending on the requirements.

Similar content being viewed by others

Literature Cited

A. Maier, F. Shmidt, and S. Shtrasburger, Chernye Metally, 7, 3–13 (1968).

E. Kaun, H. Lebmann, H. Wladika, and W. Zimnik, Bänder Bleche, Rohre, 3, 154 (1970).

W. Duckworth et al., J. Iron Steel Inst.,207, 854–71 (1969).

K. Irvine et al., J. Iron Steel Inst.,205 (1967).

A. P. Gulyaev, Toughness and Cold Brittleness of Structural Steels [in Russian], Mashinostroenie, Moscow (1969).

A. G. Nasibov, Yu. I. Matrosov, and A. V. Rudchenko, "Effect of vanadium, niobium, carbon, and silicon on the properties of low-pearlitic steels", Metal. i Term. Obrabotka Metal., 4, 19–24 (1973).

Additional information

Central Scientific-Research Institute of Ferrous Metallurgy. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 1, pp. 27–34, January, 1974.

Rights and permissions

About this article

Cite this article

Matrosov, Y.I., Nazibov, A.G. & Golikov, I.N. Properties of low-pearlitic steels with vanadium and niobium after controlled rolling. Met Sci Heat Treat 16, 28–34 (1974). https://doi.org/10.1007/BF00679197

Issue Date:

DOI: https://doi.org/10.1007/BF00679197