Conclusions

-

1.

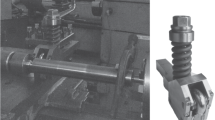

A technique has been developed for bulk-surface hardening of heavily loaded roller bearing rings.

-

2.

It was found that rings of heavily loaded roller bearings for railroad cars manufactured from high-carbon steel with controlled hardenability and subjected to bulk-surface hardening have a higher structural strength than rings of ESR steel ShKh15SG.

Similar content being viewed by others

Literature Cited

Operation of Axle Roller Bearings at High speeds [in Russian], Trudy TsNII MPS, No. 405, Transport (1970), p. 8.

K. Z. Shepelyakovskii, Induction Hardening of Machine Parts [in Russian], Mashinostroenie, Moscow (1971), p. 156.

Ya. R. Rauzin, Heat Treatment of Chromium Steel [in Russian], Mashgiz, Moscow (1963), p. 233.

Additional information

Moscow Evening Metallurgical Institute. TsNII MPS. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 1, pp. 17–21, January, 1974.

Rights and permissions

About this article

Cite this article

Shepelyakovskii, K.Z., Devyatkin, V.P., Ushakov, B.K. et al. Induction hardening of roller bearing parts. Met Sci Heat Treat 16, 19–22 (1974). https://doi.org/10.1007/BF00679195

Issue Date:

DOI: https://doi.org/10.1007/BF00679195