Conclusions

-

1.

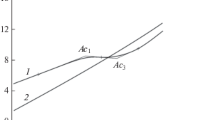

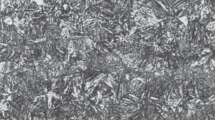

Steels for pressing high-strength alloys must contain M6C carbide in order to retain a high yield strength (80–120 kgf/mm2) at temperatures up to 650–720°.

-

2.

The heat resistance is highest (730–740°) and the notch toughness lowest (a n=0.8–1.5 kgf-m/cm2) for the steel with ∼8–9% W.

-

3.

Steels of the first group (2Kh6V8M2K8 type) are intended for pressing without substantial dynamic loads and intensive cooling. They should be quenched from 1190–1210° and tempered at 700–710° (HRC 50-51) or 745–750° (HRC 45-46). Steels of the second group (2Kh5V5M2K5 type) are used for pressing with dynamic loads and intensive cooling. They are quenched from 1190–1230° and tempered at 620–625° (HRC 50-51) or at 680–685° (HRC 45-46).

Similar content being viewed by others

Literature cited

L. S. Kremnev, Yu. A. Geller, and T. G. Sagadeva, “Steels for hot deformation of hard-to-work alloys,” ‘Stal’, No. 12, 1118 (1970).

Yu. A. Geller, Tool Steels [in Russian], Metallurgiya, Moscow (1975).

L. S. Kremnev and V. A. Brostrem, “Heat resistance of tool steels and alloys,” Metalloved. Term. Obrab. Met., No. 3, 46 (1973).

Additional information

Moscow Machine-Tool Institute. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 8, pp. 62–64, August, 1977.

Rights and permissions

About this article

Cite this article

Geller, Y.A., Sagadeeva, T.G. & Tokmin, A.M. Die steels with high heat resistance and toughness. Met Sci Heat Treat 19, 706–708 (1977). https://doi.org/10.1007/BF00673867

Issue Date:

DOI: https://doi.org/10.1007/BF00673867