Conclusions

-

1.

Slow cooling in the α→β range tends to improve the ductility and lower the strength of alloy VT20. With rapid cooling both from α→β temperatures and in the β range the ductility decreases and the strength increases slightly, especially with quenching from temperatures in the α→β range.

-

2.

The low-cycle fatigue strength decreases most for notched samples after slow cooling from temperatures in the β range.

-

3.

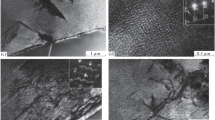

Redistribution of alloying elements occurs during slow cooling, with segregation of molybdenum, vanadium, and zirconium in the phase boundaries, forming an interlayer of stable β phase at 20°.

Similar content being viewed by others

Literature cited

C. Chen, Corrosion,27, No. 2, 30 (1971).

S. Z. Bokshtein et al., Diffusion Processes in Metals [in Russian], Naukova Dumka, Kiev (1966).

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 1, pp. 66–69, January, 1978.

Rights and permissions

About this article

Cite this article

Fedorov, V.N., Borisova, E.A. Effect of structure and phase composition on the mechanical properties of titanium alloy VT20. Met Sci Heat Treat 20, 73–76 (1978). https://doi.org/10.1007/BF00670451

Issue Date:

DOI: https://doi.org/10.1007/BF00670451