Conclusions

-

1.

The nucleate boiling time depends on the shape and size of the quenched body and also the pressure of the cooling medium.

-

2.

By changing the pressure in the region of nucleate boiling one can control the surface temperature of the piece and thus delay or accelerate the transformation of austenite to martensite.

-

3.

The difference in the cooling rate of steel parts during quenching in water and in aqueous solutions (electrolytes) is due to the presence of local vapor films. In the absence of film boiling the physical properties of the cooling medium have a negligible effect on the temperature field.

-

4.

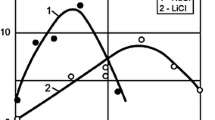

The generalized effective Biot criterion, as calculations showed, remains constant in the region of nucleate boiling regardless of the shape or size of the body, which agrees with experimental data.

-

5.

With quenching of steel machine parts in electrolytes in which the effect of the electric double layer is greatest there is either no film boiling or it can be neglected. This is indicated by the agreement between the values of the Biot criterion obtained experimentally and by calculation on the assumption that film boiling is absent.

Similar content being viewed by others

Literature cited

N. I. Kobasko, “Means of overcoming self-distortion and crack formation during quenching of metallic parts,” Metalloved. Term. Obrab. Met., No. 4, 12 (1975).

M. A. Mikheev, Fundamentals of Heat Transfer [in Russian], Gosénergoizdat, Moscow-Leningrad (1956).

V. I. Tolubinskii, “The possibility of determining the average growth rate of vapor bubbles,” in: Thermophysics and Heat Engineering [in Russian], No. 23, Naukova Dumka, Kiev (1973), p. 3.

N. I. Kobasko, “Thermal processes during quenching of steel,” Metalloved. Term. Obrab. Met., No. 3, 3 (1968).

Ya. I. Frenkel', Kinetic Theory of Liquids [in Russian], Nauka, Leningrad (1975).

G. M. Kondrat'ev, Thermal Measurements [in Russian], Mashgiz, Moscow (1957).

V. I. Fedorov and N. I. Kobasko, “Calculations of cooling time during quenching of bodies with complex shapes,” Metalloved. Term. Obrab. Met., No. 4, 59 (1972).

Additional information

Institute of Technical Thermophysics, Academy of Sciences of the Ukrainian SSR. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 1, pp. 31–36, January, 1978.

Rights and permissions

About this article

Cite this article

Kobasko, N.I. Effect of pressure on quenching of steel. Met Sci Heat Treat 20, 31–35 (1978). https://doi.org/10.1007/BF00670438

Issue Date:

DOI: https://doi.org/10.1007/BF00670438