Summary

-

1.

Heating in a tunnel furnace (10 m long, pipes moving through at the rate of 0.4 m/min) at 1200–1230°C ensures the desired grain size (grades 3–7) in steam boiler pipes of Kh18N12T steel.

-

2.

An increase in the heating rate during heat treatment decreases the difference in the grain sizes.

-

3.

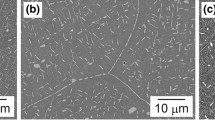

At lower heating temperatures the grains in steel containing titanium are smaller, while at higher temperatures they are larger, than in the steel without titanium.

-

4.

At the same temperature the microstructure of Kh18N12T steel containing 0.44% Ti consists of larger grains than that of steel with 0.65% Ti.

Similar content being viewed by others

Literature cited

G. A. Lebedev, A. M. Parshin, I. E. Kolosov, and I. I. Pechnikov, MiTOM (1964), No. 1

I. E. White and I. V. Freeman. Énergetika i énergeticheskie mashiny, No. 2. (1963).

S. S. Gorelik, Metal Science and Heat Treatment, Vol. 1, Chapter 38 [in Russian], Moscow, Metallurgizdat (1961).

Additional information

Nikopol'skii Yuzhnotrubnyi Plant Translated from Metallovedenie i Temicheskaya Obrabotka Metallov, No. 12, pp. 40–43, December, 1965.

Rights and permissions

About this article

Cite this article

Vil'yams, O.S., Bol'shova, N.M. & Koval', M.Y. Influence of the time and temperature of heating on the grain size of Kh18N12T steel. Met Sci Heat Treat 7, 817–820 (1966). https://doi.org/10.1007/BF00666974

Issue Date:

DOI: https://doi.org/10.1007/BF00666974