Abstract

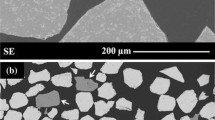

A method of long-term Sulfidation that involves generating sulfur vapor from dissociation of Ag2S or from transformation of NiS to Ni3S2+x is described. Sulfidation tests of iron samples showed the approach to be essentially valid. At 1023 K, Ag2S dissociation of Ag2S gives rise to\(p_{s_2 } = 7.9 \times 10^{ - 6} \) atm and, in the presence of an inert carrier gas, efficient transport of sulfur to the metal was effected. Liberated silver grew in the form of discrete whiskers, hence did not interfere with continued dissociation of Ag2S. Equilibration of NiS with Ni3S2+x occurs at\(p_{s_2 } = 1.4 \times 10^{ - 4} \) atm at 1023 K but, with continued loss of sulfur to the metal, the nonstoichiometric Ni3S2±x predominates and the ambient\(p_{s_2 } \) is no longer constant. Thus for long-term studies, Sulfidation with NiS/Ni3S2+x mixtures is suitable only for metals that sulfidize slowly or at rates independent of the ambient\(p_{s_2 } \). Using mainly the NiS-Ni3S2+x mixture as sulfur source, sulfidation tests up to 72 h at 1023 K were conducted on an Fe-20 at.% Al alloy. Sulfidation was apparently insensitive to the ambient\(p_{s_2 } \)and formation of a three-layer FeS/(Fe, Al)3S4/Al2S3 scale with internal precipitation zone proceeded at similar rates, and a relationship involving coupled diffusion is proposed. At longer exposure times, transformation of FeS to (Fe, Al)3S4 became extensive. Mechanical failure of the scale, followed by rapid healing beneath the original precipitation, also occured after extended reaction periods (>50 hr).

Similar content being viewed by others

References

R. A. Meussner and C. E. Birchenall,Corrosion 13, 677 (1957).

R. A. McKee and R. E. Druschel, J. Electrochem. Soc.130, 898 (1983).

D. L. Douglass, V. S. Bhide, and E. Vireberg,Oxid. Met,16, 29 (1981).

B. S. Lee and R. A. Rapp,J. Electrochem. Soc. 131, 2998 (1984).

D. L. Douglass and M. Z. Wu,Oxid. Met. 22, 45 (1984).

E. M. Fryt, V. S. Bhide, W. W. Smeltzer, and J. S. Kirkaldy,J. Electrochem. Soc. 126, 683 (1979).

K. C. Mills,Thermodynamic Data for Inorganic Sulfides, Selenides and Tellurides (Butterworths, London, 1974).

P. C. Patnaik and W. W. Smeltzer,Oxid. Met. 23, 53 (1985).

S. R. Shatynski,Oxid. Met. 11, 307 (1977).

P. J. Smith, P. R. S. Jackson, and W. W. Smeltzer,J. Electrochem. Soc. 134, 1424 (1987).

C. Wagner,Trans. AIME 194, 214 (1952).

H. Schmalzried and C. Wagner,Trans. AIME 227, 539 (1963).

T. Rosenqvist,J. Iron Steel Inst. 179, 37 (1954).

H. E. Evans, D. A. Hilton, R. A. Holm, and S. J. Webster,Oxid. Met. 19, 1 (1983).

P. R. S. Jackson and W. W. Smeltzer, to be published.

P. C. Patnaik and W. W. Smeltzer,J. Electrochem. Soc. 131, 2688 (1984).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Smith, P.J., Smeltzer, W.W. A method for long-term sulfidation of metal at low sulfur pressures and its application to sulfidation of an Fe-20 at.% Al alloy at 1023 K. Oxid Met 28, 291–308 (1987). https://doi.org/10.1007/BF00666724

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00666724