Abstract

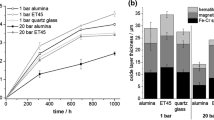

This work evaluated the adherence of oxide grown in air and synthetic exhaust gas on Fe-20Cr-5Al alloys containing strong sulfide-forming elements: Ca, Mg, Y, Ce, La, Ti, and Zr. Results support the theory that reactive elements provide good oxide adherence on alumina-forming materials primarily by tying up sulfur as stable Sulfides; however, other influences on adherence were found. Highly volatile elements, such as Ca and Mg, lose their sulfur-controlling ability by diffusing out of the matrix and into the growing oxide scale. Zirconium results in the growth of an extensive network of oxide pegs into the substrate which improves adherence. Titanium segregates to the alumina scale and acts as a sink for S in the matrix. In synthetic exhaust gas (N2+CO2+H2O), local oxide spalling was observed and was shown to be caused by H2O in the atmosphere. The added benefits of Ti and Zr, i.e., forming oxide pegs and sinks for S, improve adherence in this environment.

Similar content being viewed by others

References

D. R. Sigler, Oxidation behavior of Fe-20Cr-5Al rare earth alloys in air and synthetic exhaust gas.Oxid. Met. 36(1/2), 57–80 (1991).

C. S. Wukusick and J. F. Collins, An iron-chromium-aluminum alloy containing yttrium.Mater. Res. Stand. 4(12), 637–646 (1964).

J. K. Tien and F. S. Pettit, Mechanism of oxide adherence on Fe-25Cr-4Al (Y or Sc) alloys.Metall. Trans. 3(6), 1587–1599 (1972).

D. R. Sigler, Aluminum oxide adherence on Fe-Cr-Al alloys modified with group IIIB, IVB, VB, and VIB elements.Oxid. Met. 32(5/6), 337–355 (1989).

T. Swinden, Iron Alloy Suitable for Electrical Resistances, U.S. Patent 2,210,308, August 6, 1940.

M. Yamanaka, K. Ohmura, S. Matsumoto, S. Shibata, T. Yashiro, and A. Kasahara, Rolled High Aluminum Stainless Steel Foil for Use as a Substrate for a Catalyst Carrier, U.S. Patent 4,870,046, September 26, 1989.

U. Brill, U. Heubner, and F. Hofmann, Influence of Rare Earth Metal Additions on the Heat Resistance of Fe-20Cr-5Al Foils for Metallic Catalyst Supports, presented at the Symposium on Stainless Steels for Automotive Applications, ASM Materials Week 1987, Cincinnati, Ohio, October 1987.

J. Stringer, The effect of alloying on oxidation: Quantitative treatments.Metall. Rev. 11, 113–128 (1966).

B. Lustman, The intermittent oxidation of some nickel-chromium base alloys.Trans. TMS-AIME 188(8), 995–996 (1950).

E. J. Felten, High-temperature oxidation of Fe-Cr base alloys with particular reference to Fe-Cr-Y alloys.J. Electrochem. Soc. 108(6), 490–495 (1961).

H. Pfeiffer,Werkst. Korros. 8, 574–579 (1957).

J. E. Antill and K. A. Peakall, Influence of an alloy addition of yttrium on the oxidation behaviour of an austenitic and a ferritic stainless steel in carbon dioxide.J. Iron Steel Inst. 205, 1136–1142 (1967).

J. M. Francis and J. A. Jutson, High temperature oxidation of an Fe-Cr-Al-Y alloy in CO2.Corros. Sci. 8, 445–449 (1968).

F. A. Golightly, F. H. Stott, and G. C. Wood, The influence of yttrium additions on the oxide-scale adhesion to an iron-chromium-aluminum alloy.Oxid. Met. 10(3), 163–187 (1976).

J. E. McDonald and J. G. Eberhart, Adhesion in aluminum oxide-metal systems.Trans. TMS-AIME 233(3), 512–517 (1965).

J. L. Smialek and R. Browning, Current Viewpoints on Oxide Adherence Mechanisms, NASA Technical Memorandum 87168, 1985.

A. W. Funkenbusch, J. G. Smeggil, and N. S. Bornstein, Reactive element-sulfur interaction and oxide scale adherence.Metall. Trans. 16A(6), 1164–1166 (1985).

J. G. Smeggil, A. W. Funkenbusch, and N. S. Bornstein, A relationship between indigenous impurity elements and protective oxide scale adherence characteristics.Metall. Trans. 17A(6), 923–932 (1986).

J. L. Smialek, Adherent Al2O3 scales formed on undoped NiCrAl alloys.Metall. Trans. 18A(1), 164–167 (1987).

D. R. Sigler, The influence of sulfur on adherence of Al2O3 grown on Fe-Cr-Al alloys.Oxid. Met. 29(1/2), 23–43 (1988).

K. A. Gschneidner and N. Kippenhan,Thermochemistry of the Rare Earth Carbides, Nitrides, and Sulfides for Steelmaking (Rare Earth Information Center, Institute for Atomic Research, Iowa State University, Ames, Iowa, 1971).

K. C. Mills,Thermodynamic Data for Inorganic Sulphides, Selenides and Tellurides (Butterworths, London, 1974).

J. F. Elliott and M. Gleiser,Thermochemistry for Steel Making, Volume 1 (AddisonWesley, Reading, Massachusetts, 1960).

I. Barin and O. Knacke,Thermochemical Properties of Inorganic Substances (Springer-Verlag, Berlin, 1973).

I. Barin, O. Knacke, and O. Kubaschewski,Thermochemical Properties of Inorganic Substances Supplement (Springer-Verlag, Berlin, 1977).

T. Amano, S. Yajima, and Y. Saito, High-temperature oxidation behavior of Fe-20Cr-4Al alloys with small additions of cerium.Trans. Jpn. Inst. Met. 20, 431–441 (1979).

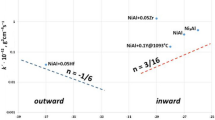

W. J. Quadakkers, H. Holzbrecher, K. G. Briefs, and H. Beske, Differences in growth mechanisms of oxide scales formed on ODS and conventional wrought alloys.Oxid. Met. 32(1/2), 67–88 (1989).

G. Ben Abderrazik, G. Moulin, and A. M. Huntz, Growth mechanism of Al2O3 scales developed on Fe-Cr-Al alloys.Solid State Ionics 22, 285–294 (1987).

B. A. Pint, J. R. Martin, and L. W. Hobbs,18O/SIMS characterization of the growth mechanism of doped and undopedα-Al2O3.Oxid. Met. 39(3/4), 167–195 (1993).

E. W. A. Young and J. H. W. De Wit The use of a18O tracer and Rutherford Backscattering spectrometry to study the oxidation mechanism of NiAl.Solid State Ionics 16, 39–46 (1985).

J. Jedlinski and S. Mrowec, The influence of implanted yttrium on the oxidation behaviour ofβ-NiAl.Mater. Sci. Eng. 87, 281–287 (1987).

D. F. Mitchell, R. Prescott, M. J. Graham, and J. Doychak, SIMS Studies of Oxide Growth onβ-NiAl. 3rd International SAMPE Metals Conference, Oct. 20–22, 1992, pp. M78–M91.

K. P. R. Reddy, J. L. Smialek, and A. R. Cooper,18O tracer studies of Al2O3 scale formation on NiCrAl alloys.Oxid. Met. 17(5/6), 429–449 (1982).

P. T. Moseley, K. R. Hyde, B. A. Bellamy, and G. Tappin, The microstructure of the scale formed during the high temperature oxidation of FeCrAl alloy steel.Corros. Sci. 24(6), 547–565 (1984).

S. Taniguchi and T. Shibata, Cyclic oxidation behavior of Ni3Al-0.1B base alloys containing a Ti, Zr, or Hf Addition.Oxid. Met. 25(3/4), 210–216 (1986).

D. R. Sigler, Oxide Whisker Growth on Contaminated Aluminum-Containing Stainless Steel Foil, U.S. Patent 4,588,449, May 13, 1986.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Sigler, D.R. Adherence behavior of oxide grown in air and synthetic exhaust gas on Fe-Cr-Al alloys containing strong sulfide-forming elements: Ca, Mg, Y, Ce, La, Ti, and Zr. Oxid Met 40, 555–583 (1993). https://doi.org/10.1007/BF00666391

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF00666391