Conclusions

-

1.

The effect of α' and α" phases on the mechanical properties of commercial titanium alloys of the martensite type (VT6, VT14, VT3-1, VT16) was investigated. A substantial strengthening effect (as much as 30%) in alloys VT6, VT14, and VT3-1 is due to the formation of α' phase in quenching. The best combination of strength and ductility was found for alloys of the martensite type quenched from temperatures in the α+β region near the end of the α+β→β transformation.

-

2.

The effect of Mo, V, Fe, Cr, and Mn concentrations on the properties of titanium martensite (α') was investigated. It was found that increasing the amount of β stabilizer in the α' phase increases its strength, lowering the ductility. The largest increase in strength was observed in alloys with the highest supersaturation of α' phase with the β stabilizing element.

-

3.

With increasing transformation of α' to α" phase in quenched Ti−Mo and Ti−V alloys the strength decreases gradually, although α" phase impoverished in β stabilizing elements has the same mechanical properties as α' phase. With increasing amounts of β stabilizing element the strength decreases, the ductility increasing.

-

4.

The addition of aluminum to titanium alloys with β stabilizing elements leads to an increase in the strength of α' phase and a larger increase of the strength after quenching.

-

5.

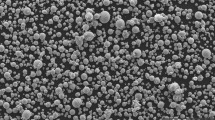

Transmission electron microscopy revealed changes in the fine structure of metastable α' martensite with increasing amounts of β stabilizers within the limits of the primary phase transformation (β→α') and in α" phase with the β→α" transformation, which determine the mechanical properties of the alloys.

The net results are basically as follows. With increasing amounts of β stabilizer within the limits of the β→α' transformation (1–4% Mo) the number of regions with twins decreases; the number of α' needles with a high dislocation density increases, and also the number of orientations. With larger amounts of β stabilizers (5–9% Mo) the number of α' needles decreases and the number of α" plates increases, the characteristic feature of which is internal twins, more even orientation of the plates, and a lower dislocation density than α' phase.

Similar content being viewed by others

Literature cited

V. N. Moiseev and L. V. Geras'kova, "Changes in structure and properties of titanium alloys in relation to heat treatment", Metal. i Term. Obrabotka Metal., 5, 3–9 (1965).

M. I. Ermolova, E. V. Polyak, and O. P. Solonina, "Phase and structural transformations in biphase commercial titanium alloys", in: Titanium Alloys for New Technology [in Russian], Nauka, Moscow (1968).

N. V. Ageev and L. A. Petrova, "Stability of β phase in titanium alloys with iron and nickel", Zh. Neorgan. Khim.,4, 5, 1092 (1959).

V. N. Gridnev et al., "Mechanism of phase transformations in Ti−Cr alloys", in: Problems of Physics of Metals and Metal Science [in Russian], No. 12, Izv. AN Ukrainian SSR (1961), p. 37.

T. Williams, R. Taggart, and D. Polonis, Met. Trans.,1, 2265 (1970).

Yu. A. Bogoryatskii, in: Problems of Metals and Physics of Metals [in Russian], Metallurgizdat, No. 5 (1958).

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 8, pp. 45–49, August, 1975.

Rights and permissions

About this article

Cite this article

Moiseev, V.N., Polyak, É.V. & Sokolova, A.Y. Martensite strengthening of titanium alloys. Met Sci Heat Treat 17, 687–691 (1975). https://doi.org/10.1007/BF00664318

Issue Date:

DOI: https://doi.org/10.1007/BF00664318