Conclusions

-

1.

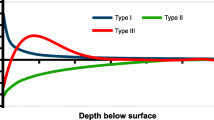

Burnishing of electrolytic iron deposits is accompanied by intensive hardening that reaches 30%. With further hardening the electrolytic iron deposit may peel off. With increasing hardness of the deposit the hardenability decreases.

-

2.

For repair of mining machinery parts we recommend the following conditions:

For single-roller burnishing: load P=200–300 kg; number of passes, one.

For multi-roller burnishing: interference 0.15–0.2 mm.

Similar content being viewed by others

Literature cited

M. P. Melkov, Hard Facing of Autotractor Parts [in Russian], Avtotransizdat, Moscow (1962).

E. G. Konovalov and V. A. Sidorenko, Rotational Finishing and Hardening Surface Treatments [in Russian], Vysshaya Shkola, Minsk (1962).

S. N. Aivazyan, Statistical Study of Relationships [in Russian], Metallurgiya, Moscow (1968).

V. K. Vigdorchik et al., Microhardness of Metals [in Russian], Metallurgizdat, Moscow (1963).

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 10, pp. 69–70, October, 1974.

Rights and permissions

About this article

Cite this article

Morozov, G.I., Morozov, V.I. Hardenability of electrolytic deposits of iron during burnishing. Met Sci Heat Treat 16, 888–890 (1974). https://doi.org/10.1007/BF00664264

Issue Date:

DOI: https://doi.org/10.1007/BF00664264