Conclusions

-

1.

A new process of combined low-temperature carbonitriding with quenching of the surface layer has been developed to improve the wear resistance of machine parts.

-

2.

Carbonitriding is conducted at 690–700°. In the first 2–3 h the surface of the steel is austenitized in a mixture of 5–10% NH3+90–95% N2 for carbon and low-alloy steels and in 30% NH3+70% N2 for highalloy steels.

In the following 2–5 h carbonitriding occurs at the same temperature in an atmosphere of carburizing gases and ammonia, followed by quenching in oil.

-

3.

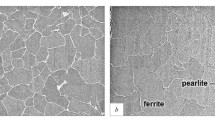

After this new treatment of steels 20Kh and 40Kh a diffusion layer 0.4–0.7 mm thick is formed that consists of a carbonitride zone 10–20 μ thick at the surface, a martensite zone with HV 700–800 to a depth of 0.08–0.12 mm, and a transition zone 0.25–0.5 mm deep.

Similar content being viewed by others

Literature cited

B. Prijenosil, Carbonitriding [in Russian], Mashinostroenie, Leningrad (1969).

I. S. Kozlovskii, Chemicothermal Treatment of Gears [in Russian], Mashinostroenie, Moscow (1970).

Yu. M. Lakhtin, Physical Basis of Nitriding Process [in Russian], Mashgiz, Moscow (1948).

Additional information

Moscow Highway Institute. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 10, pp. 8–11, October, 1974.

Rights and permissions

About this article

Cite this article

Lakhtin, Y.M., Neustroev, G.N. & Botov, V.M. Low-temperature carbonitriding of steel combined with quenching of the surface layer. Met Sci Heat Treat 16, 823–826 (1974). https://doi.org/10.1007/BF00664242

Issue Date:

DOI: https://doi.org/10.1007/BF00664242