Conclusions

-

1.

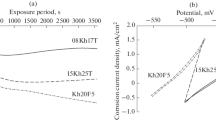

Reducing the carbon content of steels 000Kh25 and 000Kh28 to 0.005% does not eliminate susceptibility to ICC.

-

2.

The susceptibility to ICC of low-carbon ferritic steels after heating at high temperatures depends on the cooling rate. Quenching in water increases the resistance of these steels to ICC.

-

3.

Stabilizing annealing at 780°C for 1 h is an effective method of increasing the resistance of low-carbon ferritic steels to ICC.

Similar content being viewed by others

Literature cited

A. S. Zubchenko, A. A. Kolyada, and N. A. Karpov, Avtomaticheskaya Svarka,228, 3, 5–8 (1972).

B. A. Movchan, Electron Beam Melting of Metals [in Russian], Znanie, Kiev (1973).

R. Hodes, Corrosion,27, 3, 119–127 (1971).

R. Hodes, Corrosion,27, 4, 164–167 (1971).

R. Hodes, Corrosion,28, 2, 69–75 (1972).

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 12, pp. 33–35, December, 1974.

Rights and permissions

About this article

Cite this article

Tokareva, T.B., Ershova, N.I. & Zubchenko, A.S. Intercrystalline corrosion of low-carbon high-chromium ferritic steels. Met Sci Heat Treat 16, 1034–1036 (1974). https://doi.org/10.1007/BF00664044

Issue Date:

DOI: https://doi.org/10.1007/BF00664044