Conclusions

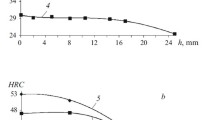

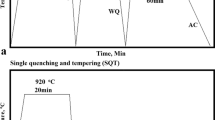

Reducing the temperature and increasing the holding time in isothermal quenching improve the elastic characteristics of springs. The best properties were obtained after isothermal quenching at 310–330° for 25–35 min.

Similar content being viewed by others

Literature cited

A. G. Rakhshtadt, Spring Alloys [in Russian], Metallurgizdat, Moscow (1965).

A. A. Sazonov, Metal. i Term. Obrabotka Metal., No. 11 (1969).

M. V. Gedeon, Heat Treatment of Truck Springs. Advanced Technology of Heat Treatment [in Russian], Mashgiz, Moscow-Sverdlovsk (1961).

Additional information

Perm' Polytechnical Institute. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 1, pp. 66–67, January, 1971.

Rights and permissions

About this article

Cite this article

Marchenko, V.G. Isothermal quenching of steel 60S2. Met Sci Heat Treat 13, 72–73 (1971). https://doi.org/10.1007/BF00663786

Issue Date:

DOI: https://doi.org/10.1007/BF00663786