Summary

-

1.

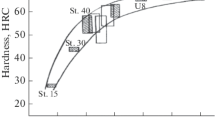

Cementation of steels containing 12% or more Cr makes it possible to obtain a wear-resistant layer 1.5–2.5 mm thick consisting of a large amount of chromium carbide (Cr7C8) and martensite.

-

2.

The wear resistance of the case hardened layer in a hydroabrasive medium is either equal or superior to the wear resistance of high-chromium white cast irons 300Kh12M and IChKh28N2. At the same time, the resistance of the case hardened samples to bending is 1.5–2 times higher than that of high chromium cast irons.

-

3.

The best combination of wear resistance and mechanical strength was achieved by case hardening and quenching 9Kh18 steel.

-

4.

The optimum conditions of the chemicothermal treatment which ensures high wear resistance are cementation at 1050°C for 3Kh13 steel and cementation at 1080–1100°C for 9Kh18 steel. The cementation time is 10–15h; precooling to 900–950°C is followed by quenching in oil from the precooling temperature and by tempering at 180°C.

Similar content being viewed by others

Additional information

VNIIPTUGLEMASh Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 11, pp. 33–37, November, 1965

Rights and permissions

About this article

Cite this article

Gamol'skaya, Z.M., Guterman, V.M. & Kotina, M.M. Increase of the wear resistance of machine parts operated in hydroabrasive media. Met Sci Heat Treat 7, 744–747 (1966). https://doi.org/10.1007/BF00663633

Issue Date:

DOI: https://doi.org/10.1007/BF00663633