Conclusions

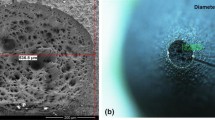

As the result of hydrostatic extrusion, the ultimate strength of steel 20 increases from 40 kg/mm2 in the original condition to 74 kg/mm2 with 70% deformation. The reduction of the ductility is explained by cold working of the ferrite matrix and the oriented arrangement of pearlite colonies in the structure.

Similar content being viewed by others

Literature cited

L. V. Prozorov, M. A. Kostava, and V. D. Revtov, Extrusion of Metals with High-Pressure Liquids [in Russian], Mashinostroenie, Moscow (1972).

A. I. Kolpashinikov and V. A. Vyalov, Hydrostatic Extrusion of Metals [in Russian], Metallurgiya, Moscow (1973).

L. T. Timoshuk, Mechanical Tests of Metals [in Russian], Metallurgiya, Moscow (1971).

R. Honeycombe, Plastic Deformation of Metals [Russian translation], Mir, Moscow (1972).

E. Aernoudt and L. Sevillano, J. Iron Steel Inst.,211, No. 10, 718–725 (1973).

Additional information

Donets Physicotechnical Institute. Kommunar Mining-Metallurgical Institute. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 5, pp. 71–72, May, 1975.

Rights and permissions

About this article

Cite this article

Galkin, A.A., Chernyi, Y.F., Koviko, V.S. et al. Strain hardening of steel 20 in hydrostatic extrusion. Met Sci Heat Treat 17, 439–440 (1975). https://doi.org/10.1007/BF00663230

Issue Date:

DOI: https://doi.org/10.1007/BF00663230