Conclusions

-

1.

In the process of heating alloy 80N2M with 0.018–0.02% S to temperatures above 1200°C the sulfides located in grain boundaries go into solution in the metallic matrix. This process is most complete at 1250–1350°C.

-

2.

Heating above 1300°C leads to considerable oxidation of the alloy in the grain boundaries and impairs the plasticity.

-

3.

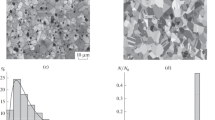

The nucleation of new grains in the process of hot rolling occurs at the boundaries of columnar crystals of the original cast structure. The largest size of recrystallized grains corresponds to the region of transition from partial retention of the cast structure to complete recrystallization.

-

4.

The number of sulfide inclusions in the bulk of new recrystallized grains is smaller than in the cast matrix, which indicates redistribution of sulfur between the bulk of the grains and the grain boundaries in the process of recrystallization.

-

5.

We determined the effect of rolling conditions, cooling rate of the strip after deformation, and the final rolling temperature on the formation of fine-grained structure in hot rolled strips.

Similar content being viewed by others

Literature cited

W. Tiller, The Art and Science of Crystal Growing, Wiley, New York (1962), Chap. 15, p. 121.

L. N. Larikov, "Effect of soluble impurities on growth rate of recrystallization centers", in: Problems of Physics of Metals and Metal Science [in Russian], No. 10, Izd. AN UkrSSR, Kiev (1959), pp. 121–129.

S. I. Bulat and I. N. Golikov, "Method of investigating distribution of temperatures through sections of ingots during rolling", in: Transactions of Central Scientific-Research Institute of Ferrous Metallurgy [in Russian], No. 32, Metallurgizdat, Moscow (1963), pp. 101–104.

S. S. Gorelik et al., "Recrystallization of hot worked austenite in the process of continuous cooling", Metal. i Term. Obrabotka Metal., No. 10, 2–6 (1971).

Additional information

I. P. Bardin Central Scientific-Research Institute of Ferrous Metallurgy. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 5, pp. 35–38, May, 1975.

Rights and permissions

About this article

Cite this article

Levinzon, V.K., Putimtsev, B.N. & Leskov, B.A. Structural and phase transformations in alloy 80N2M with sulfur. Met Sci Heat Treat 17, 400–403 (1975). https://doi.org/10.1007/BF00663217

Issue Date:

DOI: https://doi.org/10.1007/BF00663217