Conclusions

-

1.

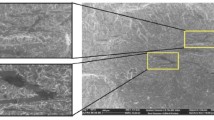

The use of preliminary carburizing for steels 4Kh5MFS, 4Kh2M1FN, and 4Kh5V2FS results in a layer of chromium carbide 30–50% deeper after chromizing, and also a higher surface hardness after quenching and tempering.

-

2.

Preliminary carburizing improves the heat resistance, red hardness, and hot wear as compared with diffusion chromizing (without carburizing) or standard heat treatment.

-

3.

Production tests of mandrels and matrixes of cable presses made of steels 4Kh5MFS and 4Kh2M1FN indicate that after the combination treatment the durability is three to four times higher than that of tools made of steel 3Kh2V8F subjected to standard heat treatment.

Similar content being viewed by others

Literature Cited

Yu. A. Geller, Tool Steels [in Russian], Metallurgizdat, Moscow (1968), p. 496.

M. F. Pankratov and A. D. Kozhevnikova, Diffusion Chromizing of Dies for Extrusion of Tubing and Sections of Aluminum Alloys [in Russian], Tekhnologiya Legkikh Splavov, No. 3, Nauchno-Tekhnicheskii Byulleten' VILS, Moscow (1971), p. 88.

V. S. Malygin and Yu. N. Griboedov, "Improving the durability of dies by combined coatings of chromium, nitrogen, and carbon", Vestnik Mashinostroeniya, 9, 61–64 (1972).

V. S. Malygin and Yu. N. Griboedov, "Improving the durability of dies by diffusion chromizing", Kuznechno-Shtampovochnoe Proizvodstvo, 3, 11–13 (1973).

Yu. N. Griboedov and B. I. Yunts, "Technology of diffusion chromizing of power machine parts with powder", in: New in the Technology of Heat and Chemicothermal Treatment [in Russian], Trudy TsNIITMASh, No. 35, Izd. ONTI (1963), pp. 41–47.

I. E. Tutov and S. V. Markin, Basic Characteristics of the Heat Resistance of Steels for Mandrels and Die-Casting Dies [in Russian], TsBNTI, Moscow (1958), pp. 81–87.

Yu. N. Griboedov et al., Technology of Diffusion Chromizing of Mandrels and Dies of Cable Presses [in Russian], Improvement of Chemicothermal Treatment Processes, 13-73-14, NIIINFORMtyazhmash.

Additional information

Central Scientific-Research Institute of Heavy Machine Construction. VNIIKP. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 1, pp. 30–32, January, 1975.

Rights and permissions

About this article

Cite this article

Griboedov, Y.N., Isakova, E.I., Édel'man, A.S. et al. Combined saturation of die steels with chromium and carbon. Met Sci Heat Treat 17, 30–33 (1975). https://doi.org/10.1007/BF00663084

Issue Date:

DOI: https://doi.org/10.1007/BF00663084