Abstract

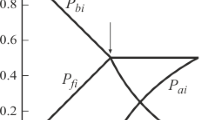

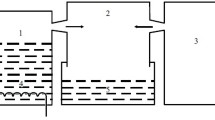

Injection moulded plaques of polystyrene and of two types of high density polyethylene have been produced under different moulding conditions. The mean densityϱ of each plaque together with its surface microhardnessV H have been measured. Polystyrene shows only a slight increase inϱ with increasing mould temperatureT m together with a reduced spread inϱ andV H values. In polyethylene, however,ϱ andV H both increase linearly withT m, giving a usefulV H againstϱ relation, which is attributed to increased percentage crystallinity.

Similar content being viewed by others

References

A. Redner,Plast. Eng. Feb. (1987) 37.

R. G. Treuting andW. T. Read Jr,J. Appl. Phys. 22 (1951) 130.

“American Institute of Physics Handbook” (McGraw Hill Book Co., New York, 1972).

F. J. Balta Calleja, D. R. Rueda, R. S. Porter andW. T. Mead,J. Mater. Sci. 15 (1980) 765.

A. Zehavi andF. E. Filisko,J. Macromol. Sci. Phys. B21 (1982) 47.

R. F. Roe,J. Appl. Phys. 48 (1977) 4085.

I. G. Brown, R. E. Wetton, M. J. Richardson andN. G. Savill,Polymer 19 (1978) 659.

D. R. Rueda, F. J. Balta Calleja andR. K. Bayer,J. Mater. Sci. 16 (1981) 3371.

B. T. A. Chang andJ. C. M. Li,J. Mater. Sci. 15 (1980) 1364.

R. L. Ballman, T. Shusman andH. L. Toor,Mod. Plast. 37 (1959) 105.

I. M. Barrie,Plast. Polym. 37 (1969) 463.

M. R. Kamal andS. Kenig,Polym. Engng Sci. 12 (1972) 294.

J. L. Berger andC. G. Gogos,ibid. 13 (1973) 209.

J. L. White,ibid. 15 (1975) 44.

M. R. Kamal, Y. Kuo andP. H. Doan,ibid. 15 (1975) 863.

E. Broyes, C. Gutfinger andZ. Tadmor,Trans. Soc. Rheol. 19 (1975) 423.

J. F. Steven, A. Galsky, K. K. Wang, I. Chen andD. H. Reber,Polym. Engng Sci. 17 (1977) 666.

J. L. White andW. Dietz,ibid. 19 (1979) 1081.

A. I. Isayev andC. A. Hieber,Rheol. Acta. 19 (1980) 168.

B. L. Evans, To be published.

E. S. Clark,Plast. Eng. 30 (1974) 73.

M. R. Kantz, H. D. Newman andF. H. Stigale,J. Appl. Polym. Sci. 16 (1972) 1249.

V. Tan andM. R. Kamal,ibid. 22 (1978) 2341.

M. Fujiyama, H. Awaya andS. Kimura,ibid. 21 (1977) 3291.

M. Fujiyama andS. Kimura,ibid. 22 (1978) 1225.

M. Fujiyama andK. Azuma,ibid. 23 (1979) 2807.

S. Y. Hobbs andC. F. Pratt,ibid. 19 (1975) 1701.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Evans, B.L. The microhardness of injection moulded polystyrene and polyethylene. J Mater Sci 24, 173–182 (1989). https://doi.org/10.1007/BF00660950

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00660950