Conclusions

-

1.

Forging of the VT3-1 and VT14 alloys at temperatures of the β-region leads to the formation of large grains, a nonuniform, large-needle microstructure, low ductility (particularly the reduction in section), and low resistance to relaxation.

-

2.

The decrease of the initial forging temperature to the temperature of the α+β region, other conditions being equal, leads to the formation of a more uniform equiaxial and small-grained structure and increases the ductility and the relaxation resistance.

-

3.

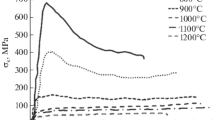

An increase of the testing temperature of the VT3-1 alloy to 100°C has no effect on the resistance to stress relaxation during the 1000 h of testing; in the case of the VT14 alloy the relaxation resistance decreases.

The resistance of the VT3-1 alloy to stress relaxation is higher than that of the VT14 alloy and of the 60Kh3G8N8V alloy used at the present time for banding.

-

4.

The VT14 alloy is more susceptible to deformation at high temperatures than the VT3-1 alloy not only in terms of its mechanical characteristics but also in terms of resistance to stress relaxation.

Similar content being viewed by others

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 3, pp. 60–62, March, 1966

Rights and permissions

About this article

Cite this article

Arkovenko, G.I., Grekov, N.A., Lyapicheva, N.F. et al. Variation of stress relaxation of titanium alloys as a function of the conditions of deformation at high temperatures. Met Sci Heat Treat 8, 237–239 (1966). https://doi.org/10.1007/BF00660398

Issue Date:

DOI: https://doi.org/10.1007/BF00660398