Abstract

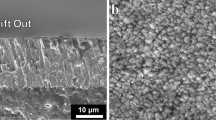

It is difficult to alloy lithium and nickel using conventional techniques. One alternative is ion implantation. Implantation of lithium in nickel, at 500°C to doses at which the solubility is exceeded, causes an unusual form of precipitation. Electron microscopy revealed the precipitates to have truncated octahedral shapes with {111} planes for sides, and {100} planes truncating the corners. They resemble voids and helium bubbles in nickel. The lithium precipitates on dislocations. The alloy was internally oxidized in order to obtain evidence for lithium presence in nickel. Electron diffraction analysis revealed the presence of LixNi1−xO compound with an ordered NaCl-type structure, forming topotaxially with the nickel, in thin film form, inside the octahedra. Attempts to fabricate the ordered LixNi1−xO were unsuccessful; only the disordered form could be produced. It was concluded that the presence of the crystallographic planes of nickel and/or the thin film oxide form are required for the formation of the ordered compound.

Similar content being viewed by others

References

AIP Handbook, 3rd ed., D. E. Gray, ed. (McGraw-Hill, New York, 1972).

Y. Takeuchi, K. Mochizuki, M. Watanabe, and I. Obnita,Metall. 20(1), 2 (1960).

H. Pfeifer and K. Hauffe,Z. Metall. 43, 364 (1945).

E. J. W. Verwey, P. W. Haaijman, F. C. Romeijn, and G. W. van Oosterhoot,Philips Res., Rep. 5, 173 (1950).

G. Dearnaley,Treatise on Materials Science and Technology, Vol. 18, p. 257. (Ibid., 1980).Nucl. Instrum. Methods 182/183, 899 (1981).

P. D. Goode,Inst. Phys. Con. Ser. No. 28, 154 (1976).

Zhou Peide, F. H. Stott, P. P. M. Procter, and W. A. Grant,Oxid. Met. 16, 409 (1981).

B. J. Kestel,Ultramicroscopy 9, 379 (1982).

A. Taylor, J. R. Wallace, E. A. Ryan, A. Phillipides, and J. R. Wrobel,Nucl. Instrum. Methods 189, 211–217 (1981).

J. P. Biersack and L. G. Haagmark,Nucl. Instrum. Methods 174, 257 (1980).

B. J. Kestel, Polishing Methods for Metallic and Ceramic Transmission Electron Microscopy Specimens, ANL Pub. No. 80–120 (July 1981).

P. B. Hirsch, A. Howie, R. B. Nicholson, D. W. Pashley, and M. J. Whelan,Electron Microscopy of Thin Crystals (Butterworths, London, 1965).

J. W. Eddington,Practical Electron Microscopy in Materials Science, Monograph 2, Maxmillan Philips Tech. Library, Eindhoven (1973).

R. W. G. Wyckoff,Crystal Structures, 2nd ed., Vol. 1, p. 242 (1965).

H. Riecke and R. Hoppe,Z. An. All. Chemie 392(3), 193 (1972).

J. C. Anderson and M. Schieber,Phys. Chem. Solids 25, 961 (1964).

Ibid.,Acta Cryst. 16, A21 (1963).

C. J. Toussaint,J. Appl. Cryst. 4, 293 (1971).

R. J. Moore and J. White,J. Mat. Sci. 9, 1401 (1974).

Author information

Authors and Affiliations

Additional information

Work supported by the U.S. Department of Energy.

Rights and permissions

About this article

Cite this article

Seshan, K., Baldo, P. & Wiedersich, H. Internal oxidation of lithiated nickel. Oxid Met 24, 1–15 (1985). https://doi.org/10.1007/BF00659594

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00659594